- Home

- Factories

- Processes

- Products

- News

- Download

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

Customized

DS

Scrap Steel Processing Aluminum Can Recycling Machine Producer,Scrap Treatment Plant Aluminum Can Recycling Machine Producer

Eddy current separator is mainly used to recycle copper, aluminum and other non-ferrous metals from industrial waste and solid waste. It is widely used in environmental protection industries, like waste classification, waste electrical and electronic equipment recycling, and the treatment of non-ferrous metal industrial materials. The separating efficiency is of a wide range of non-ferrous metals, which features strong adaptability, and reliable mechanical structure, high efficiency in separation.

Description | Recycling machine for aluminum with eddy current separator |

Type | ECS*P40 |

Application | PET flakes recycling, E waste recycling, medical glasses scrap |

| Weight Ranges | OEM |

Design Support | Pro-E, UG,SolidWorks,AutoCad, PDF |

Quality Control | Material, Dimension,Performance |

After-sales Service Provided | Engineers available to service machinery overseas for 1 year |

Product show:

Specification:

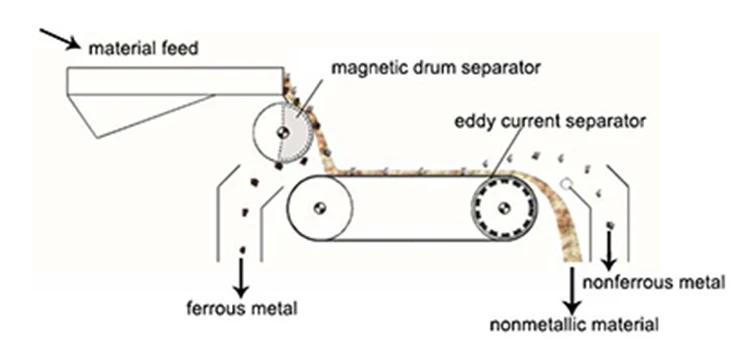

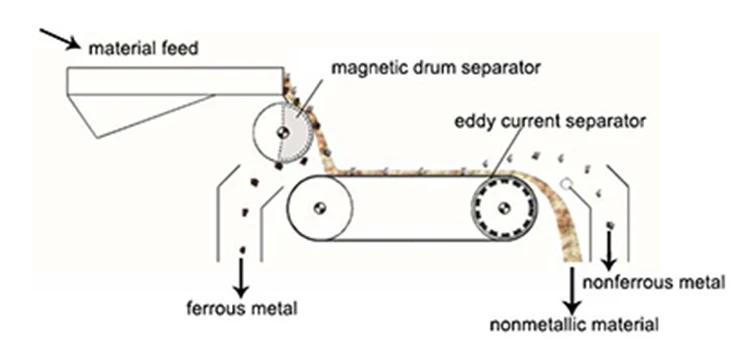

Work principle:

ISF is Located in shanyang ,China, which is a professional enterprise producing magnetic series products. Our factory has been focusing on designing and manufacturing magnetic equipment for 12 years since 2006.We are one of the earliest suppliers of magnetic separator and eddy current separator in Asia. Main products are Eddy current separator, magnetic separator, belt magnetic separator, Drum magnetic separator and Grate magnets. We could also supply you the complete resource recycling solutions such as ASR recycling, Zorba and Glass Cullet recycling.

Work shop

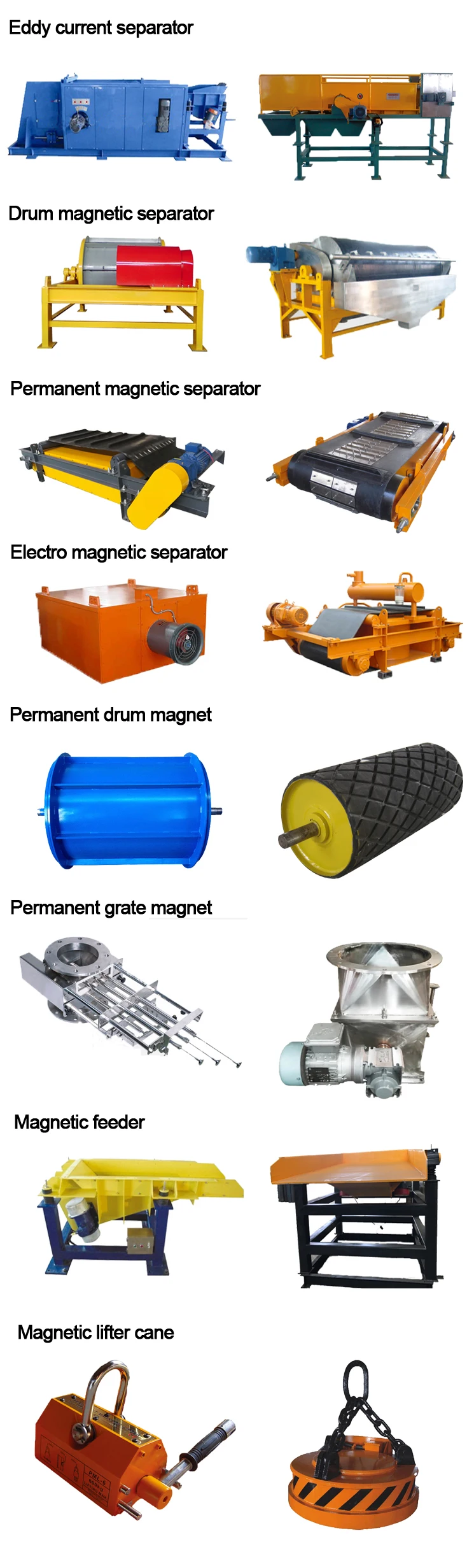

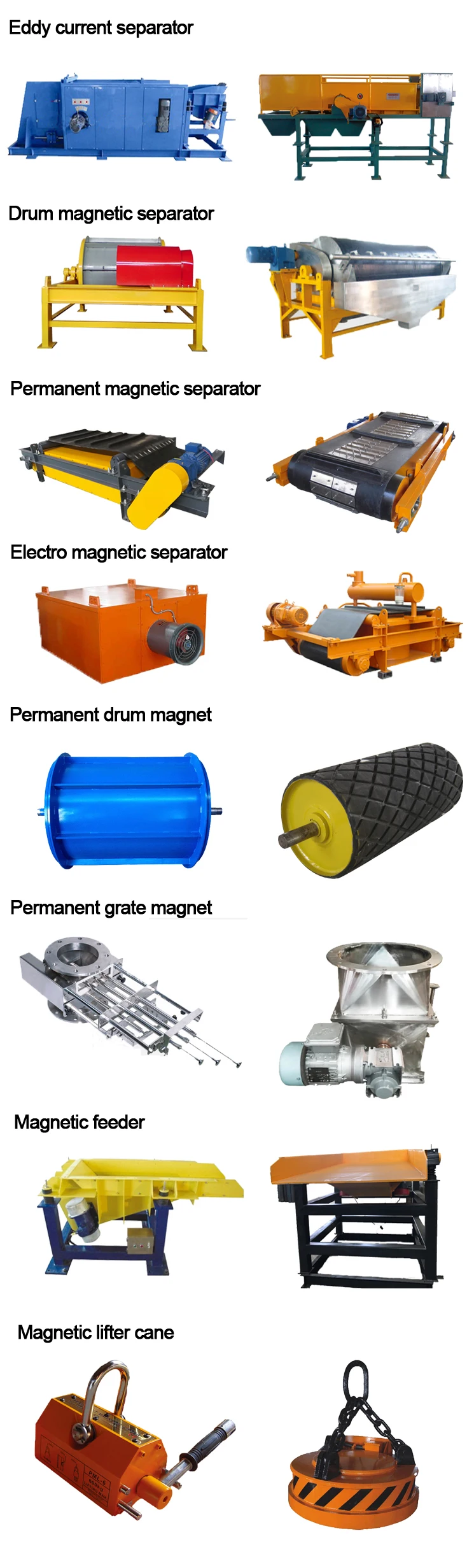

Magnet series products

With well-equipped professional engineers and strong technical ability, our company has been in this field for 15 years.

1. We cooperate with superior suppliers (Nord &Schneider) to ensure the quality.

2. Tests of materials are freely checked for the required quality of the equipment before packing.

3. Engineers are always available to service for machinery commissioning overseas, which is not only after sales service support, but also technology support .

4."Keep Improving, Pursuing Excellence" would be kept forever.

Treatable material

1. Wet type

In order to recommend the most suitable model, please let us know the material`s situation, including the composition , size ,handling capacity and ferrous content.

2.Dry type

In order to recommend the most suitable model, please let us know

1.the material`s situation .including the composition , size ,handling capacity and ferrous content.

2.the material thickness transported on conveyor .

3.The width of conveyor bel

3.Which type should I use for my recycling plant?

In order to recommend the most suitable model, please let us know follow info:

1.material`s situation .including the composition , size ,handling capacity and ferrous content

2.the material thickness transported on conveyor belt.

3.The shape and width of the conveyor belt .

Scrap Steel Processing Aluminum Can Recycling Machine Producer,Scrap Treatment Plant Aluminum Can Recycling Machine Producer

Eddy current separator is mainly used to recycle copper, aluminum and other non-ferrous metals from industrial waste and solid waste. It is widely used in environmental protection industries, like waste classification, waste electrical and electronic equipment recycling, and the treatment of non-ferrous metal industrial materials. The separating efficiency is of a wide range of non-ferrous metals, which features strong adaptability, and reliable mechanical structure, high efficiency in separation.

Description | Recycling machine for aluminum with eddy current separator |

Type | ECS*P40 |

Application | PET flakes recycling, E waste recycling, medical glasses scrap |

| Weight Ranges | OEM |

Design Support | Pro-E, UG,SolidWorks,AutoCad, PDF |

Quality Control | Material, Dimension,Performance |

After-sales Service Provided | Engineers available to service machinery overseas for 1 year |

Product show:

Specification:

Work principle:

ISF is Located in shanyang ,China, which is a professional enterprise producing magnetic series products. Our factory has been focusing on designing and manufacturing magnetic equipment for 12 years since 2006.We are one of the earliest suppliers of magnetic separator and eddy current separator in Asia. Main products are Eddy current separator, magnetic separator, belt magnetic separator, Drum magnetic separator and Grate magnets. We could also supply you the complete resource recycling solutions such as ASR recycling, Zorba and Glass Cullet recycling.

Work shop

Magnet series products

With well-equipped professional engineers and strong technical ability, our company has been in this field for 15 years.

1. We cooperate with superior suppliers (Nord &Schneider) to ensure the quality.

2. Tests of materials are freely checked for the required quality of the equipment before packing.

3. Engineers are always available to service for machinery commissioning overseas, which is not only after sales service support, but also technology support .

4."Keep Improving, Pursuing Excellence" would be kept forever.

Treatable material

1. Wet type

In order to recommend the most suitable model, please let us know the material`s situation, including the composition , size ,handling capacity and ferrous content.

2.Dry type

In order to recommend the most suitable model, please let us know

1.the material`s situation .including the composition , size ,handling capacity and ferrous content.

2.the material thickness transported on conveyor .

3.The width of conveyor bel

3.Which type should I use for my recycling plant?

In order to recommend the most suitable model, please let us know follow info:

1.material`s situation .including the composition , size ,handling capacity and ferrous content

2.the material thickness transported on conveyor belt.

3.The shape and width of the conveyor belt .

| | Floor 21, Block B, Fortune Building, No. 18 Xinghua Bei Street , Tiexi District, Shenyang, 110025, China. |

| | 86 15541524932 |

| | contact@sydensen.com |