- Home

- Factories

- Processes

- Products

- News

- Download

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

DS

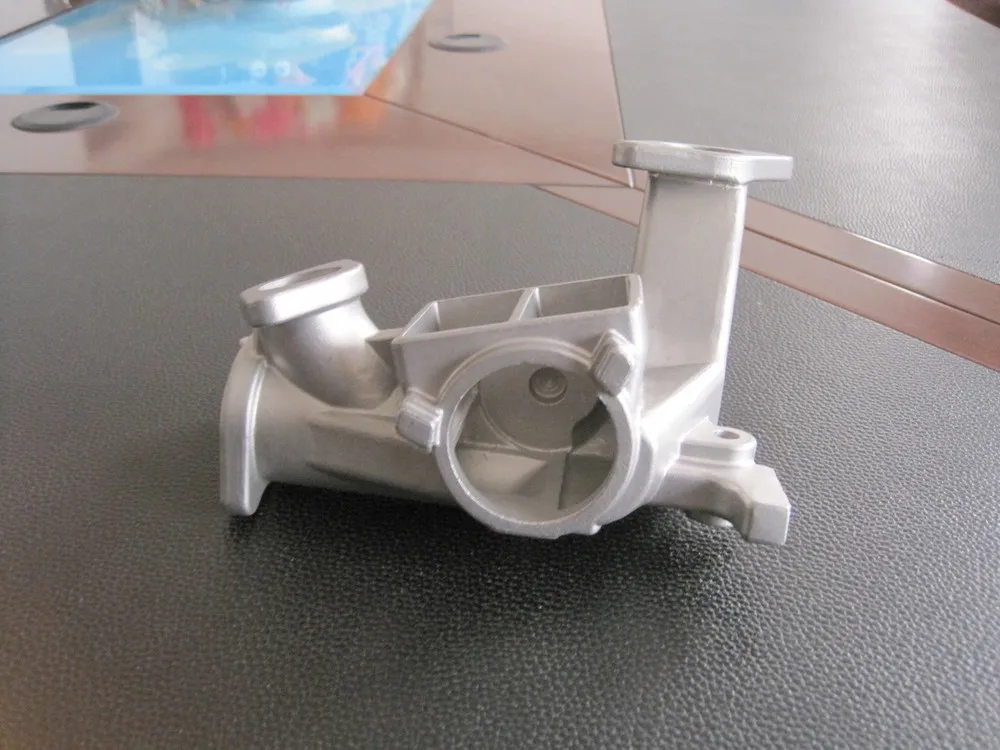

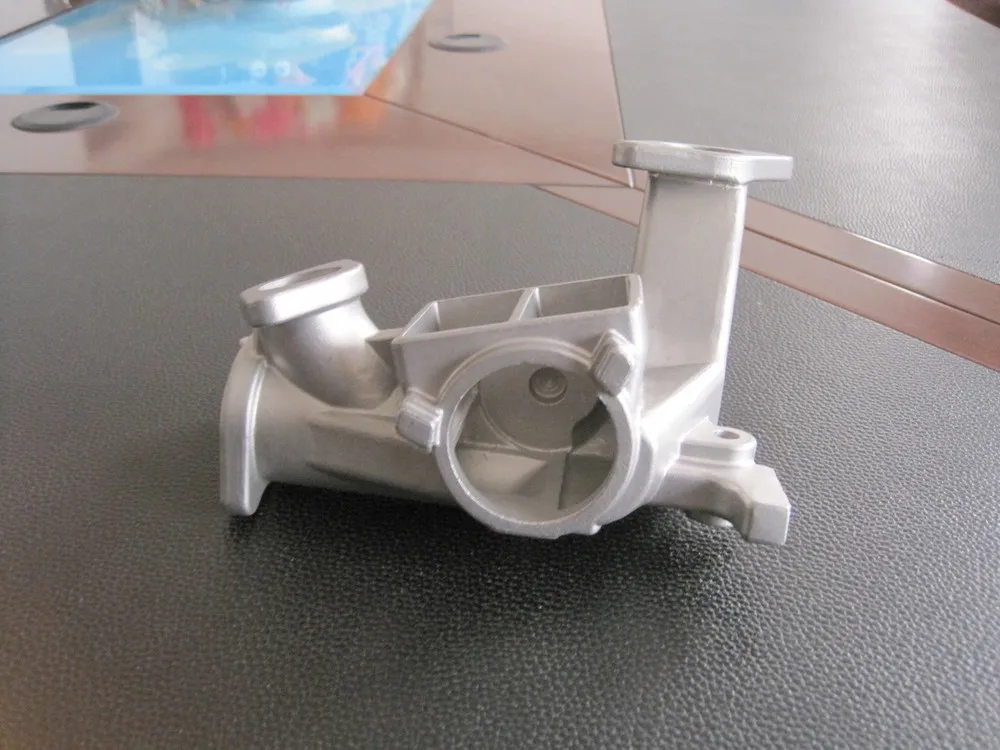

OEM precision stainless steel nickel-based alloy investment casting product

We can supply products with following features:

Material: Alloy steels, Carbon steel, Stainless steels, Grey iron, Ductile iron, Non-ferrous alloys, etc.

Processes: Investment casting/Lost wax casting (silicon glue, water glass, multilayer), Lost foam casting, Sand casting (resin sand casting, green sand casting), Shell-molding casting, Automatic molding line, etc.

High pressure die casting, Low pressure die casting, Gravity die casting, Centrifugal casting, etc.

Open die forging and close die forging, etc.

Plastic injection, Stamping, Assembling, etc.

| PROCESS | Material Grade | Weight range | Application |

Investment casting, sand casting, ESR casting Die casting | Iron: Grey iron, Ductile iron Steel: Carbon steel, Alloy steel, Stainless steel Nonferrous metal: Bronze, Brass, Al, Zinc, Ti, etc. | From 0.01Kg to 100 ton | Auto motive, agricultural machines, vessels, toolings, mining , oi l& gas machinery, locomotive industry, aerospace, hardware, contruction, engineering machinery, electrical equipment etc. |

Standard: ANSI, ASTM, DIN, JIS. BS

Inspection: 100 % self-inspection. 3rd party inspection available.

Certificate: EN 3.1 B certificate; ISO certificate, etc.

WHY BUY FROM US

We have our own factory and 15 cooperative factories, best quality mechanical products with the most competitive prices.

All our factories are ISO 9001 certified. Some of them were awarded by ISO/TS16949, PED, etc. could RT, UT, MPI, WPS&PQR certificates also can be provided if necessary

We will not only manufacture and source products for our customers, but also provide technical support, production all-time supervision and quality track service. Special request products available upon request.

| About Us |

With the help of over 20 years manufacturing experiences in the field of oil & gas, mining, power generation, transportation industries, Shenyang New Densen Casting and Forging Co., Ltd. and its 15 factories would like to help our worldwide customers to supply the best quality mechanical products with the most competitive prices. The product single weight could be from 0.01KGS TO100,000KGS. The processes could be casting, forging, stamping, machining, fabrication and assembly. The material could be various steel, iron and non-ferrous. All our factories are ISO 9001 certified. Some of them were awarded by ISO/TS16949, PED, etc. We also could provide RT, UT, MPI, WPS&PQR, etc. as per request. Densen will not only manufacture and source products for our customers, but also provide technical support, production all-time supervision and quality track service. Special request products available upon request Just inform us what you are looking for, our professional team will help you to finish the other work. |

OUR WORKSHOP:

| Quality Control | Professional precision manufacture for more than 10 years. 1. Quality control: The defective products rate is 0.1%. Imported material 100%. 2. Experienced &Responsible QC that you can reply on. 3. Each part would be given 100% test and tryout before shipment. 4. Adequate supply capacity. Punctual delivery time. 5. Best after sales service is provided. |

Packing detail: standard export packing, wooden cases, according to customer

Delivery detail: usually 30 working days ,according to the volume

OEM precision stainless steel nickel-based alloy investment casting product

We can supply products with following features:

Material: Alloy steels, Carbon steel, Stainless steels, Grey iron, Ductile iron, Non-ferrous alloys, etc.

Processes: Investment casting/Lost wax casting (silicon glue, water glass, multilayer), Lost foam casting, Sand casting (resin sand casting, green sand casting), Shell-molding casting, Automatic molding line, etc.

High pressure die casting, Low pressure die casting, Gravity die casting, Centrifugal casting, etc.

Open die forging and close die forging, etc.

Plastic injection, Stamping, Assembling, etc.

| PROCESS | Material Grade | Weight range | Application |

Investment casting, sand casting, ESR casting Die casting | Iron: Grey iron, Ductile iron Steel: Carbon steel, Alloy steel, Stainless steel Nonferrous metal: Bronze, Brass, Al, Zinc, Ti, etc. | From 0.01Kg to 100 ton | Auto motive, agricultural machines, vessels, toolings, mining , oi l& gas machinery, locomotive industry, aerospace, hardware, contruction, engineering machinery, electrical equipment etc. |

Standard: ANSI, ASTM, DIN, JIS. BS

Inspection: 100 % self-inspection. 3rd party inspection available.

Certificate: EN 3.1 B certificate; ISO certificate, etc.

WHY BUY FROM US

We have our own factory and 15 cooperative factories, best quality mechanical products with the most competitive prices.

All our factories are ISO 9001 certified. Some of them were awarded by ISO/TS16949, PED, etc. could RT, UT, MPI, WPS&PQR certificates also can be provided if necessary

We will not only manufacture and source products for our customers, but also provide technical support, production all-time supervision and quality track service. Special request products available upon request.

| About Us |

With the help of over 20 years manufacturing experiences in the field of oil & gas, mining, power generation, transportation industries, Shenyang New Densen Casting and Forging Co., Ltd. and its 15 factories would like to help our worldwide customers to supply the best quality mechanical products with the most competitive prices. The product single weight could be from 0.01KGS TO100,000KGS. The processes could be casting, forging, stamping, machining, fabrication and assembly. The material could be various steel, iron and non-ferrous. All our factories are ISO 9001 certified. Some of them were awarded by ISO/TS16949, PED, etc. We also could provide RT, UT, MPI, WPS&PQR, etc. as per request. Densen will not only manufacture and source products for our customers, but also provide technical support, production all-time supervision and quality track service. Special request products available upon request Just inform us what you are looking for, our professional team will help you to finish the other work. |

OUR WORKSHOP:

| Quality Control | Professional precision manufacture for more than 10 years. 1. Quality control: The defective products rate is 0.1%. Imported material 100%. 2. Experienced &Responsible QC that you can reply on. 3. Each part would be given 100% test and tryout before shipment. 4. Adequate supply capacity. Punctual delivery time. 5. Best after sales service is provided. |

Packing detail: standard export packing, wooden cases, according to customer

Delivery detail: usually 30 working days ,according to the volume

| | Floor 21, Block B, Fortune Building, No. 18 Xinghua Bei Street , Tiexi District, Shenyang, 110025, China. |

| | 86 15541524932 |

| | contact@sydensen.com |