- Home

- Factories

- Processes

- Products

- News

- Download

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

DS-01

DS

Description:

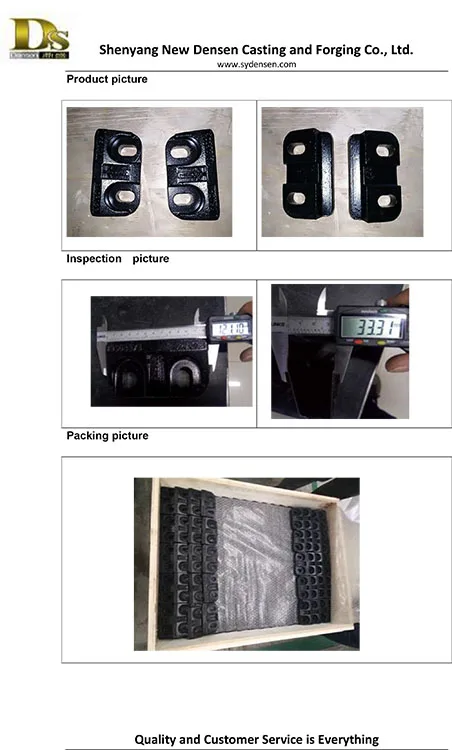

We supply two kinds of this forklift spare parts for Cascade corporation. The name is lower hook.

And we can help with custom designed solutions.

Production Details

process:

| Coated sand casting | Clay Sand Casting |

Material:

QT500-7/QT550-6

Mold:

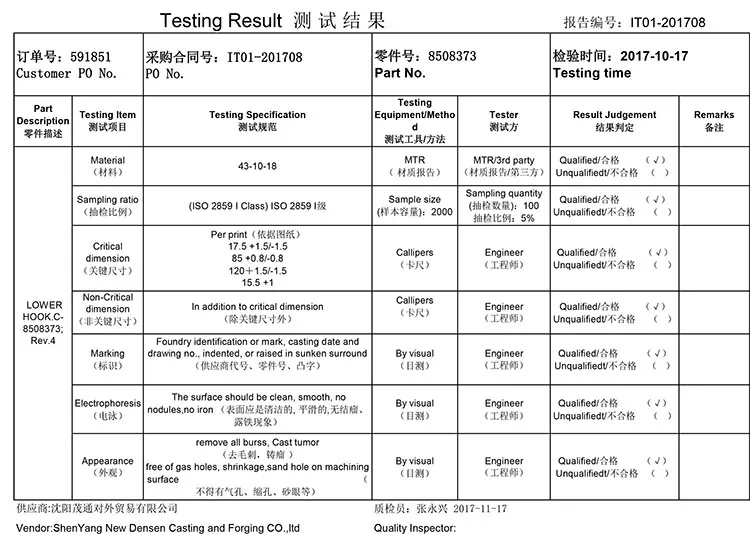

Inspection

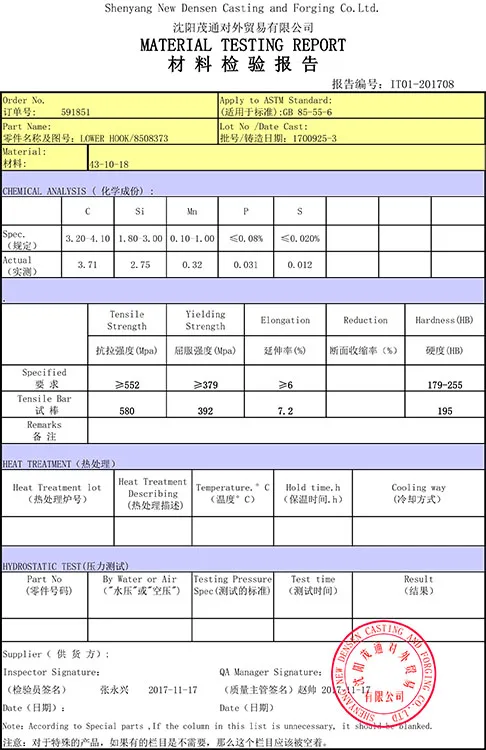

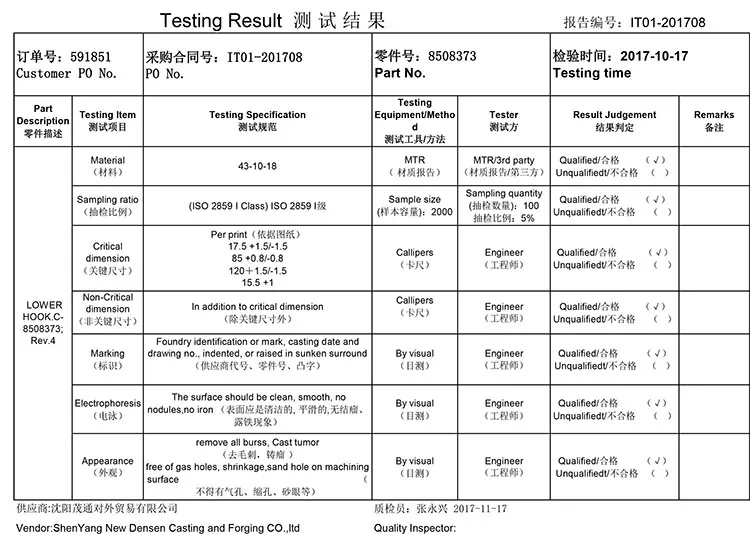

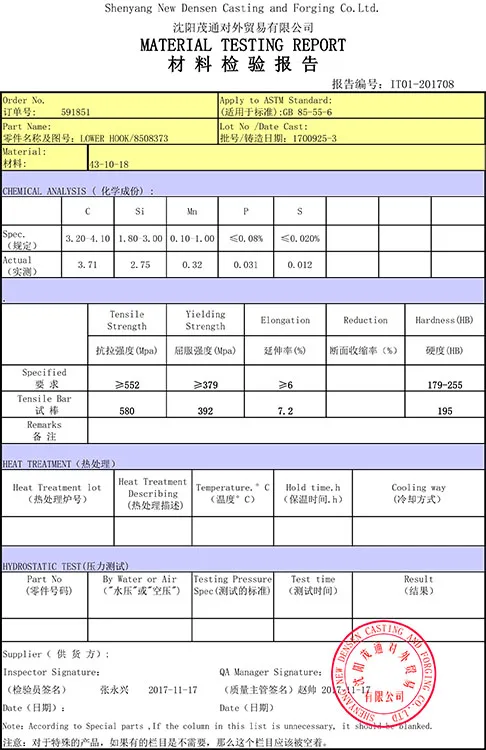

Inspection Report

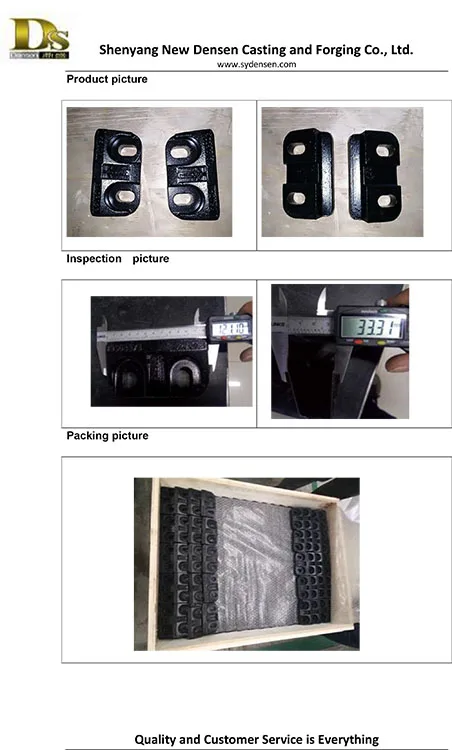

Packaging

Certification

Casting Service

Product name | OEM Sand Casting |

Technology | Clay (green) sand casting, Resin sand casting, Iron based coated sand casting |

Applicable material | Cast steel : carbon cast steel, alloy cast steel, stainless steel etc. Cast iron : gray cast iron , ductile (nodular) cast iron, malleable cast iron etc. Aluminum, bronze etc. |

Material standard | GB, ANSI, BS, DIN, JIS,ASTM,ASME,AISI |

Unit weight | 0.5kg -240tons as per customer design drawing |

MOQ | 100kg |

Main industries our products in | Oil&gas, agricultural (farm machine), forklift, pipefitting, mining, power, machinery industries, etc. |

Packing | Standard export package |

Delivery time | 30-60 days after receive order deposit generally |

Typical products we manufactured & exported | Metal core used for rubber tracks of agriculture tractor, insert blocks, gearbox house&lid used for oil drilling equipment, valve parts, pump parts and pedals, pillow blocks(bearing housing),flight drive plates, plough frames, power clamp cover, power clamp frame, heavy duty wheels etc. |

More casting service we can do | Investment casting, die casting, gravity casting, centrifugal casting ESR casting etc. |

Other manufacture service we can do | forging (free forging, die forging ), stamping, machining, welding fabrication, hydro-forming etc. |

New Densen’s business type | Not only trading company , but have our own foundry (20years), forging factory (7 years) and machining factory (4 years) |

New Densen’s value |

QC system, help factories and customers to avoid of non- conformance products |

Customers our products exported to | 70% in Europe and America; 25% in Japan; 5% in other areas. For example: CAD in Italy, BS in Japan, GE in Germany, BT in Canada, FT in USA, and many other companies in USA, UK, Canada, Germany, Israel etc. |

We strictly follow the schedule and provide weekly reports to ensure the customer to see the production status of products in real time.

We will send you quotation within 2 days.

Description:

We supply two kinds of this forklift spare parts for Cascade corporation. The name is lower hook.

And we can help with custom designed solutions.

Production Details

process:

| Coated sand casting | Clay Sand Casting |

Material:

QT500-7/QT550-6

Mold:

Inspection

Inspection Report

Packaging

Certification

Casting Service

Product name | OEM Sand Casting |

Technology | Clay (green) sand casting, Resin sand casting, Iron based coated sand casting |

Applicable material | Cast steel : carbon cast steel, alloy cast steel, stainless steel etc. Cast iron : gray cast iron , ductile (nodular) cast iron, malleable cast iron etc. Aluminum, bronze etc. |

Material standard | GB, ANSI, BS, DIN, JIS,ASTM,ASME,AISI |

Unit weight | 0.5kg -240tons as per customer design drawing |

MOQ | 100kg |

Main industries our products in | Oil&gas, agricultural (farm machine), forklift, pipefitting, mining, power, machinery industries, etc. |

Packing | Standard export package |

Delivery time | 30-60 days after receive order deposit generally |

Typical products we manufactured & exported | Metal core used for rubber tracks of agriculture tractor, insert blocks, gearbox house&lid used for oil drilling equipment, valve parts, pump parts and pedals, pillow blocks(bearing housing),flight drive plates, plough frames, power clamp cover, power clamp frame, heavy duty wheels etc. |

More casting service we can do | Investment casting, die casting, gravity casting, centrifugal casting ESR casting etc. |

Other manufacture service we can do | forging (free forging, die forging ), stamping, machining, welding fabrication, hydro-forming etc. |

New Densen’s business type | Not only trading company , but have our own foundry (20years), forging factory (7 years) and machining factory (4 years) |

New Densen’s value |

QC system, help factories and customers to avoid of non- conformance products |

Customers our products exported to | 70% in Europe and America; 25% in Japan; 5% in other areas. For example: CAD in Italy, BS in Japan, GE in Germany, BT in Canada, FT in USA, and many other companies in USA, UK, Canada, Germany, Israel etc. |

We strictly follow the schedule and provide weekly reports to ensure the customer to see the production status of products in real time.

We will send you quotation within 2 days.

| | Floor 21, Block B, Fortune Building, No. 18 Xinghua Bei Street , Tiexi District, Shenyang, 110025, China. |

| | 86 15541524932 |

| | contact@sydensen.com |