- Home

- Factories

- Processes

- Products

- News

- Download

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

DS

OEM quality assurance customized

aluminium die casting tube

OEM and Customized Design ,all available here in Densen! aluminium die casting tube

Specification Sheet: aluminium die casting tube

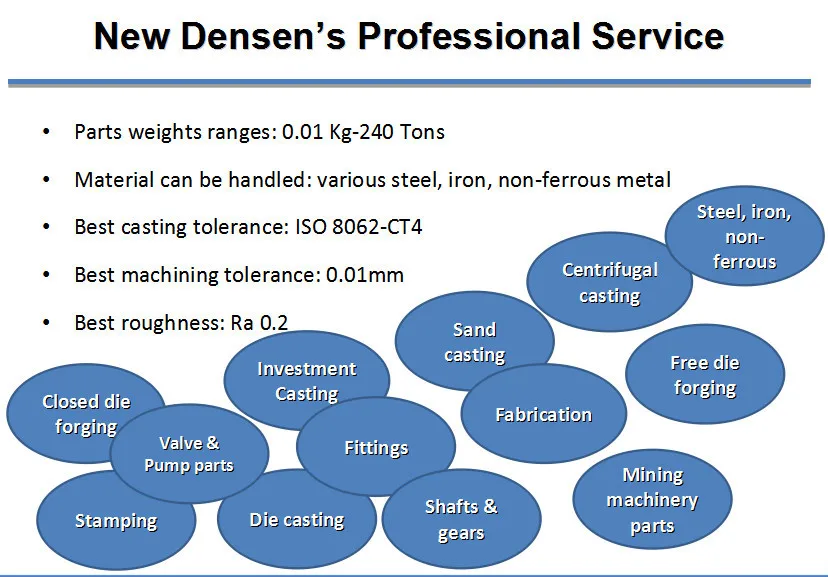

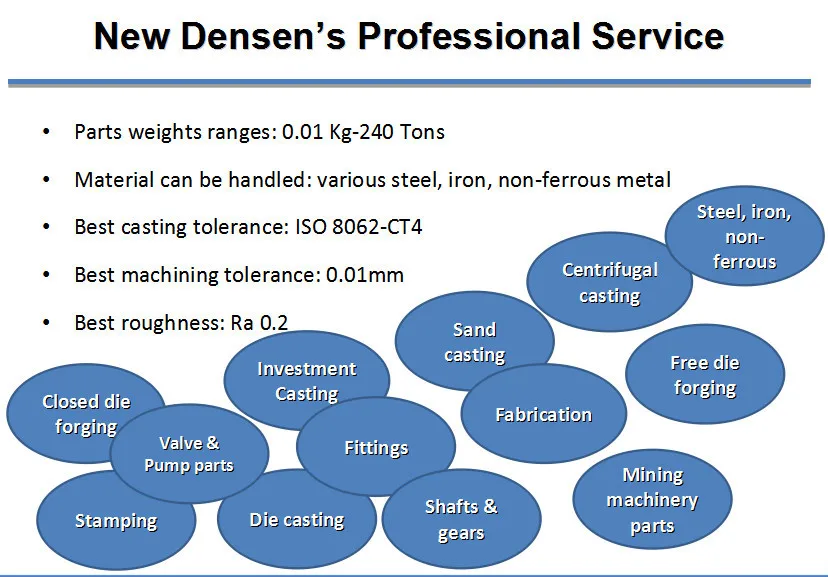

| Process | Investment casting; Sand casting; ESR casting; Die casting; |

| Material Grade | Iron: Grey iron, Ductile iron; Steel: Carbon steel, Alloy steel,Stainless steel; Nonferrous metal: Bronze, Brass, Al, Zinc, Ti, etc. |

| Weight Range | 0.01Kg to 100 ton |

| Standard | ANSI, ASTM, DIN, JIS, BS |

| Surface Finish | passivated, stain polished, mirror polished, e-coating ,ect. |

| Application | Auto motive,agricultural machines,vessels,toolings, mining ,oi l&gas machinery,locomotive industry, aerospace,hardware, contruction,engineering machinery,electrical equipment etc. |

casting tube

aluminium die casting tube

Casting Products:

casting tube

1. Quality guarantee casting tube

• Chemical checking

• Mechanical testing after heat treatment

• Dimension inspected

2. Quality document aluminium die casting tube

• Full Q.A document as per client request

3.Packing and Shipping

• Standard export package(carton/wooden case/pallet)

• Accept FOB,FAS,CNF,CIF door to door etc. or customer designated shipping agent.

4.Service aluminium die casting

• Drawing: we can translate your original drawing, offer best suggestion on design.

• Quality: we have full set quality control system to guarantee the best quality.

5.Inspection aluminium die casting tube

•Inspect in house, all our products must be checked 3 times before packing;

•Third party inspection is available upon requirement.

Die Casting Products Display: aluminium die casting tube

Besides sand casting, Investment casting,ESR casting,Die casting are all of our main foundry field. casting tube

casting tube

Casting Process: casting tube

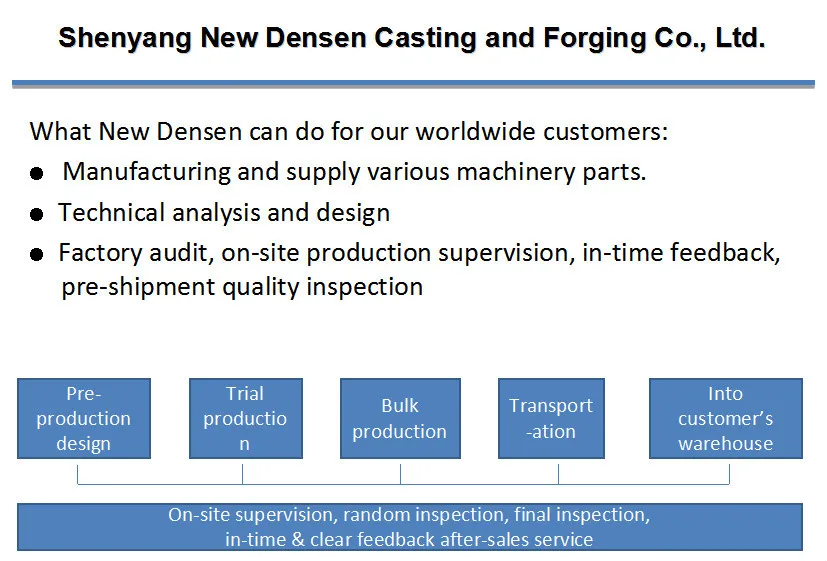

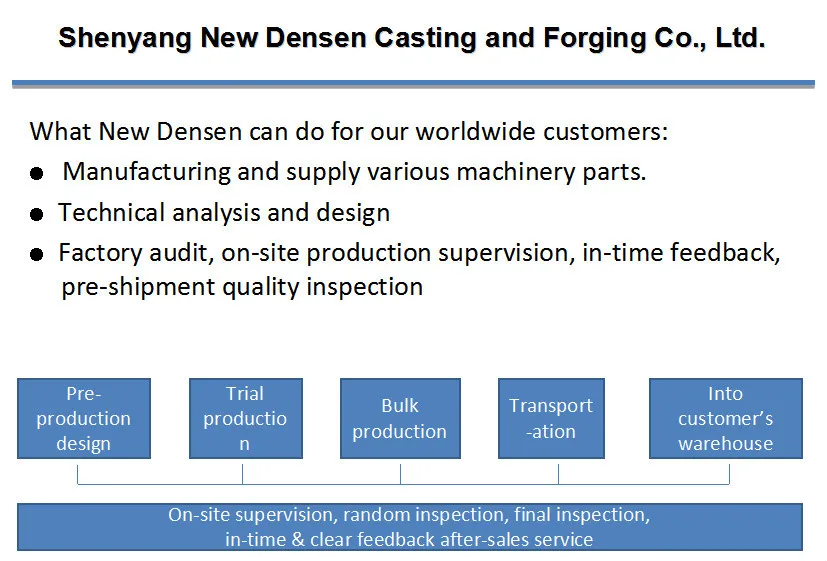

OEM AND CUSTOMIZED SERVICE: casting tube

Customized Casting ,Forging,Stamping,Machining,Welding&Fabrication Service.

One-stop service,Meet your unique needs! aluminium die casting tube

casting tube

casting tube

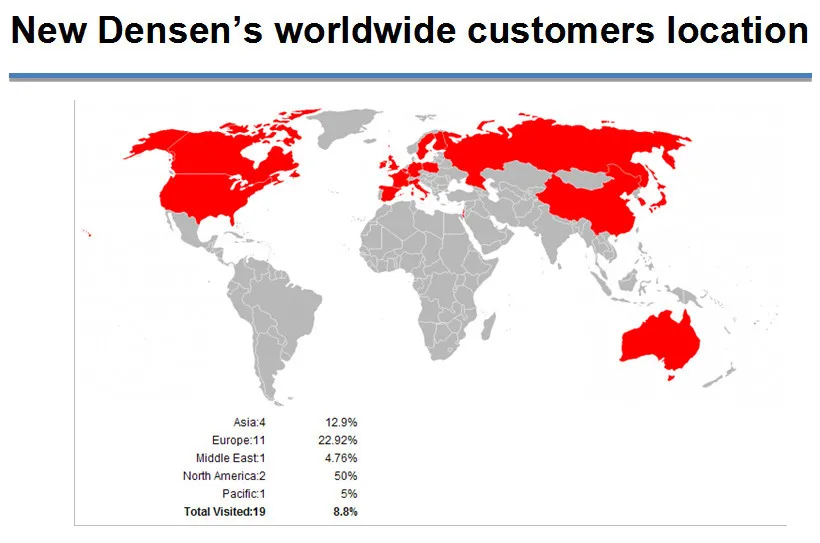

Shenyang Densen Group of Companies

Our History: aluminium die casting tube

Year 1992: Densen foundry established

Year 2007: Densen forging factory established

Year 2008: New Densen trading company established

Year 2013: Densen group established, incl. Densen foundry,

Densen forging, New Densen trading company casting tube

Year 2013: Lantian, Kailong, Xinbaolu, Yuhuan metal, SPC of SCF joined in Densen group

Year 2014: Hongyang, Wangda joined in Densen group

casting tube

Densen trading company=export window of whole group

Densen Group=Put our advantages together, to customers best satisfied service.

casting tube

casting tube

casting tube

aluminium die casting tube

If you have any questions,please feel no hesitate to contact me!

c asting tube

asting tube

aluminum die casting tube

casting tube

OEM quality assurance customized

aluminium die casting tube

OEM and Customized Design ,all available here in Densen! aluminium die casting tube

Specification Sheet: aluminium die casting tube

| Process | Investment casting; Sand casting; ESR casting; Die casting; |

| Material Grade | Iron: Grey iron, Ductile iron; Steel: Carbon steel, Alloy steel,Stainless steel; Nonferrous metal: Bronze, Brass, Al, Zinc, Ti, etc. |

| Weight Range | 0.01Kg to 100 ton |

| Standard | ANSI, ASTM, DIN, JIS, BS |

| Surface Finish | passivated, stain polished, mirror polished, e-coating ,ect. |

| Application | Auto motive,agricultural machines,vessels,toolings, mining ,oi l&gas machinery,locomotive industry, aerospace,hardware, contruction,engineering machinery,electrical equipment etc. |

casting tube

aluminium die casting tube

Casting Products:

casting tube

1. Quality guarantee casting tube

• Chemical checking

• Mechanical testing after heat treatment

• Dimension inspected

2. Quality document aluminium die casting tube

• Full Q.A document as per client request

3.Packing and Shipping

• Standard export package(carton/wooden case/pallet)

• Accept FOB,FAS,CNF,CIF door to door etc. or customer designated shipping agent.

4.Service aluminium die casting

• Drawing: we can translate your original drawing, offer best suggestion on design.

• Quality: we have full set quality control system to guarantee the best quality.

5.Inspection aluminium die casting tube

•Inspect in house, all our products must be checked 3 times before packing;

•Third party inspection is available upon requirement.

Die Casting Products Display: aluminium die casting tube

Besides sand casting, Investment casting,ESR casting,Die casting are all of our main foundry field. casting tube

casting tube

Casting Process: casting tube

OEM AND CUSTOMIZED SERVICE: casting tube

Customized Casting ,Forging,Stamping,Machining,Welding&Fabrication Service.

One-stop service,Meet your unique needs! aluminium die casting tube

casting tube

casting tube

Shenyang Densen Group of Companies

Our History: aluminium die casting tube

Year 1992: Densen foundry established

Year 2007: Densen forging factory established

Year 2008: New Densen trading company established

Year 2013: Densen group established, incl. Densen foundry,

Densen forging, New Densen trading company casting tube

Year 2013: Lantian, Kailong, Xinbaolu, Yuhuan metal, SPC of SCF joined in Densen group

Year 2014: Hongyang, Wangda joined in Densen group

casting tube

Densen trading company=export window of whole group

Densen Group=Put our advantages together, to customers best satisfied service.

casting tube

casting tube

casting tube

aluminium die casting tube

If you have any questions,please feel no hesitate to contact me!

c asting tube

asting tube

aluminum die casting tube

casting tube

| | Floor 21, Block B, Fortune Building, No. 18 Xinghua Bei Street , Tiexi District, Shenyang, 110025, China. |

| | 86 15541524932 |

| | contact@sydensen.com |