- Home

- Factories

- Processes

- Products

- News

- Download

- Contact Us

| Model Number: | |

|---|---|

| Application: | |

| Material: | |

| Dimensions: | |

| Process: | |

| Availability: | |

| Quantity: | |

Densen customized

DG

Densen customized stainless steel casting gs 20mn5 steel silica sol investment casting metal parts components

Material | Cast steel ;stainless steel (304/316/304L);cast iron |

| Weight Ranges | 0.05-100kg |

Tolernace | Controlled by ISO 8006 CT4-6 |

Design Support | Pro-E, UG,SolidWorks,AutoCad, PDF |

Quality Control | Material, Dimension,Performance,inside defects,Balance test |

Standard | ASTM,DIN,JIS,ISO,GB standards |

Product show:

Declaration:

Products shown herein are made to the requirements of specific customers and are illustrative of the types of manufacturing capabilities available within Densen group of companies.

Our policy is that none of these products will be sold to 3rd parties without written consent of the customers to whom the tooling, design and specifications belong.

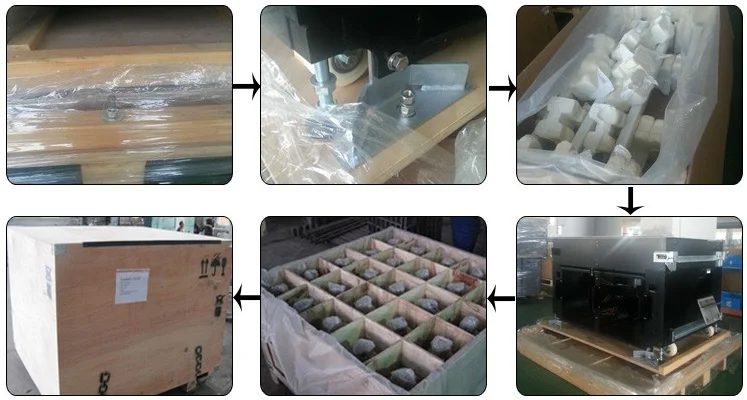

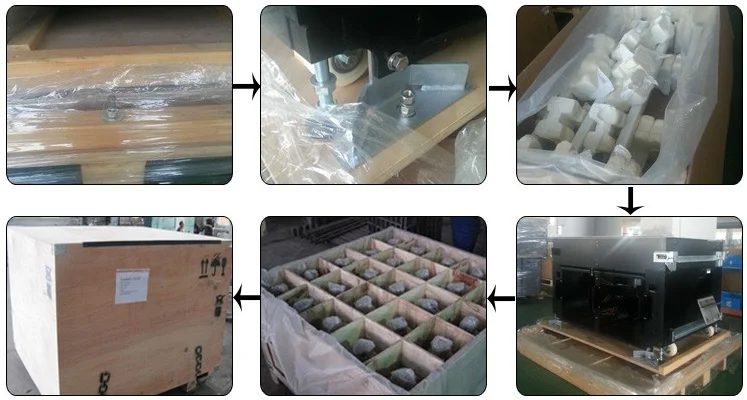

Packing detail

(1) Standard export packing: carton, crate, pallet ect.

(2) as each customer required.

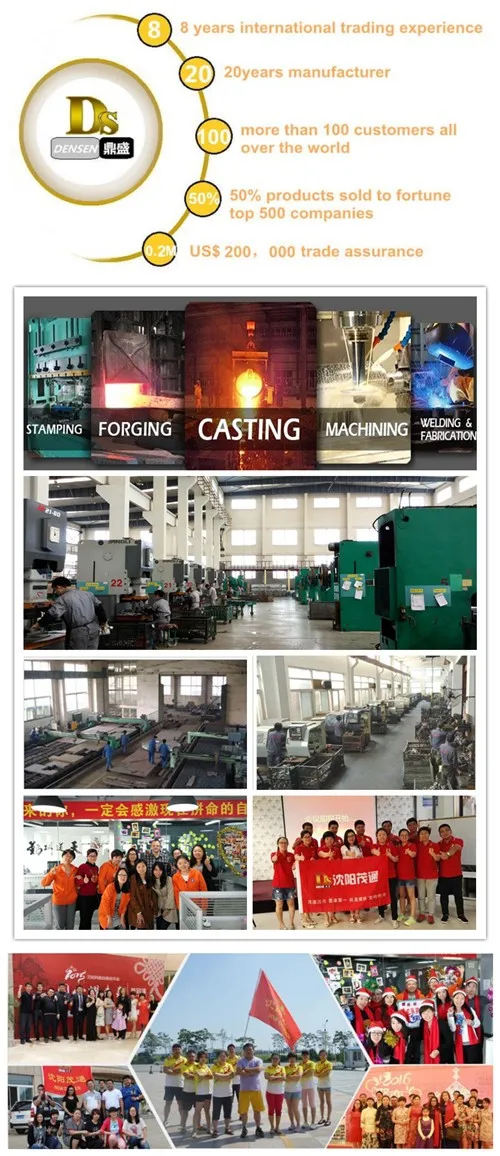

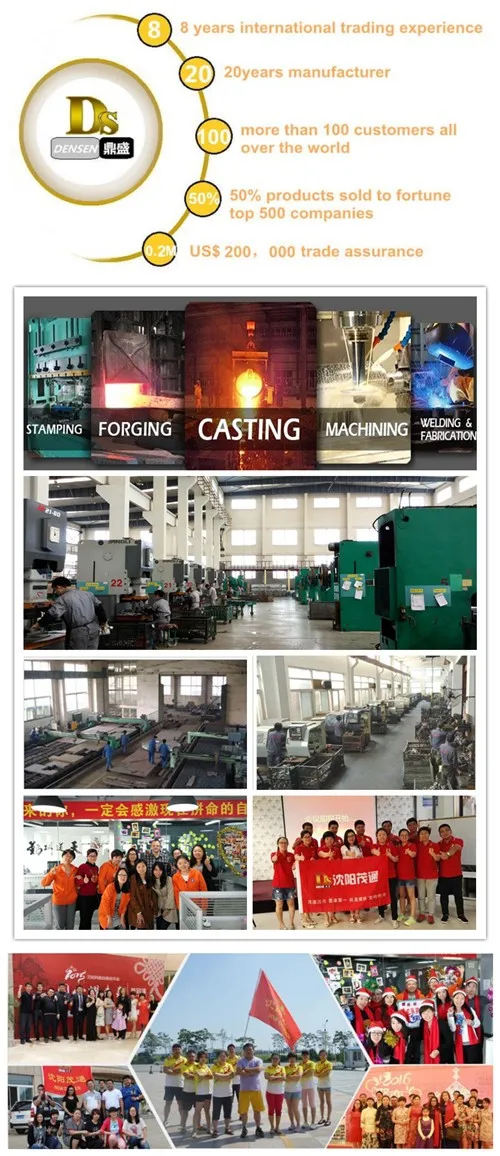

Shenyang New Densen Casting and Forging Company is the sales company of Shenyang Densen Group of Companies. Features of New Densen simply summarized as below:

1. Trusted supplier of steel, iron & non-ferrous components;

2. Extensive documented quality program in place.

3. Castings, forgings, stampings, machining, welding & fabrication services.

4. 9 related factories, over 50 joint-venture sub-contractors.

5. 25+ years of manufacturing experiences, 10+ years of exporting experience

6. 100% of products sold to overseas customers.

7. 50% of customer base is forturne 500 companies.

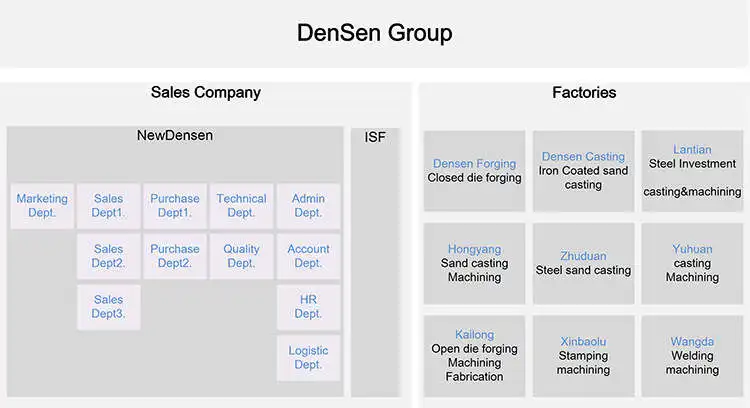

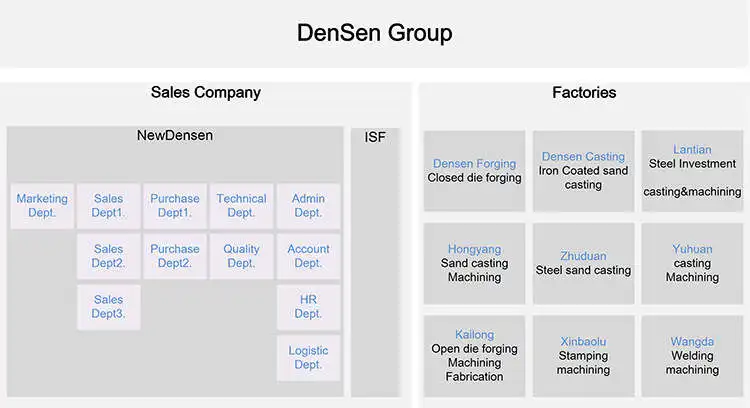

Densen Group Architecture:

Frequently Asked Question

1. Are you a manufacturer or a trader?

We are manufacturer AND trader, as we have own factories and also long term friendly cooperated sub-contractors.

That is why we could provide one-stop service to worldwide customers.

2. What can you do for customer ?

One Stop Service

1).Manufacturing and supply various machinery parts.

2). Technical analysis and design

3).Factory audit, on-site production supervision, in-time feedback, pre-shipment quality inspection

3. How could you commit the product quality

1) all our factories were ISO certified.

2) more than 50% of New Densen’s products were sold to worldwide top 500 companies which located in North American,

Western Europe, and Japan.

3) New Densen’s QC engineers will do on-site supervision and before EX-work quality inspection.

New Densen will issue inspection reports for customers’ approval before EX-work. New Densen will be

responsible for its reports and every parts no matter how long sold to customers.

4. What is your payment term?

1) Pattern and tooling: 50% prepaid as order deposit; balance 50% paid within 10 days after samples approved.

2)Sample : 50% prepaid as order deposit; balance 50% paid within 10 days after samples approved.

3)Product: 30% prepaid as order deposit;70% paid before EX-work.

If samples can’t be approved by customers and no need to redo new samples, deposit will be returned to customers.

Welcome customer place order with us through credit system (Trade Assurance), to get alibaba’s credit guarantee.

5. How long shall we get the quotation?

1-3 working days for simple products; 3-5 working days for complicated products

Densen customized stainless steel casting gs 20mn5 steel silica sol investment casting metal parts components

Material | Cast steel ;stainless steel (304/316/304L);cast iron |

| Weight Ranges | 0.05-100kg |

Tolernace | Controlled by ISO 8006 CT4-6 |

Design Support | Pro-E, UG,SolidWorks,AutoCad, PDF |

Quality Control | Material, Dimension,Performance,inside defects,Balance test |

Standard | ASTM,DIN,JIS,ISO,GB standards |

Product show:

Declaration:

Products shown herein are made to the requirements of specific customers and are illustrative of the types of manufacturing capabilities available within Densen group of companies.

Our policy is that none of these products will be sold to 3rd parties without written consent of the customers to whom the tooling, design and specifications belong.

Packing detail

(1) Standard export packing: carton, crate, pallet ect.

(2) as each customer required.

Shenyang New Densen Casting and Forging Company is the sales company of Shenyang Densen Group of Companies. Features of New Densen simply summarized as below:

1. Trusted supplier of steel, iron & non-ferrous components;

2. Extensive documented quality program in place.

3. Castings, forgings, stampings, machining, welding & fabrication services.

4. 9 related factories, over 50 joint-venture sub-contractors.

5. 25+ years of manufacturing experiences, 10+ years of exporting experience

6. 100% of products sold to overseas customers.

7. 50% of customer base is forturne 500 companies.

Densen Group Architecture:

Frequently Asked Question

1. Are you a manufacturer or a trader?

We are manufacturer AND trader, as we have own factories and also long term friendly cooperated sub-contractors.

That is why we could provide one-stop service to worldwide customers.

2. What can you do for customer ?

One Stop Service

1).Manufacturing and supply various machinery parts.

2). Technical analysis and design

3).Factory audit, on-site production supervision, in-time feedback, pre-shipment quality inspection

3. How could you commit the product quality

1) all our factories were ISO certified.

2) more than 50% of New Densen’s products were sold to worldwide top 500 companies which located in North American,

Western Europe, and Japan.

3) New Densen’s QC engineers will do on-site supervision and before EX-work quality inspection.

New Densen will issue inspection reports for customers’ approval before EX-work. New Densen will be

responsible for its reports and every parts no matter how long sold to customers.

4. What is your payment term?

1) Pattern and tooling: 50% prepaid as order deposit; balance 50% paid within 10 days after samples approved.

2)Sample : 50% prepaid as order deposit; balance 50% paid within 10 days after samples approved.

3)Product: 30% prepaid as order deposit;70% paid before EX-work.

If samples can’t be approved by customers and no need to redo new samples, deposit will be returned to customers.

Welcome customer place order with us through credit system (Trade Assurance), to get alibaba’s credit guarantee.

5. How long shall we get the quotation?

1-3 working days for simple products; 3-5 working days for complicated products

| | Floor 21, Block B, Fortune Building, No. 18 Xinghua Bei Street , Tiexi District, Shenyang, 110025, China. |

| | 86 15541524932 |

| | contact@sydensen.com |