- Home

- Factories

- Processes

- Products

- News

- Download

- Contact Us

| Application: | |

|---|---|

| QC Control: | |

| Certification: | |

| Material: | |

| Hardness: | |

| Availability: | |

| Quantity: | |

Densen Customized

OEM

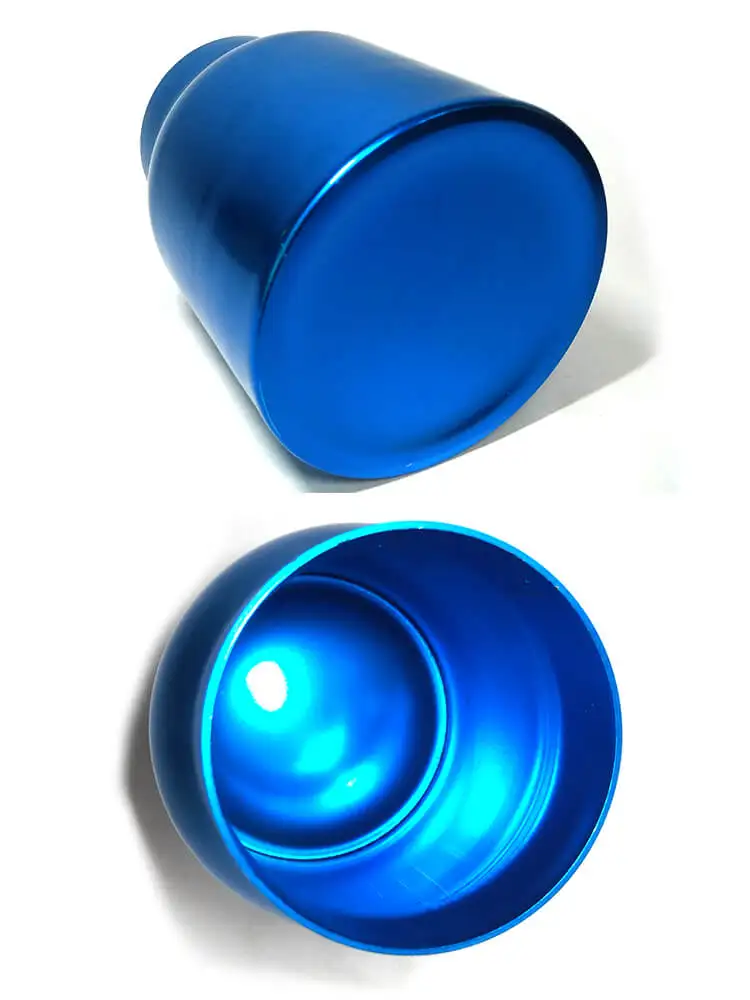

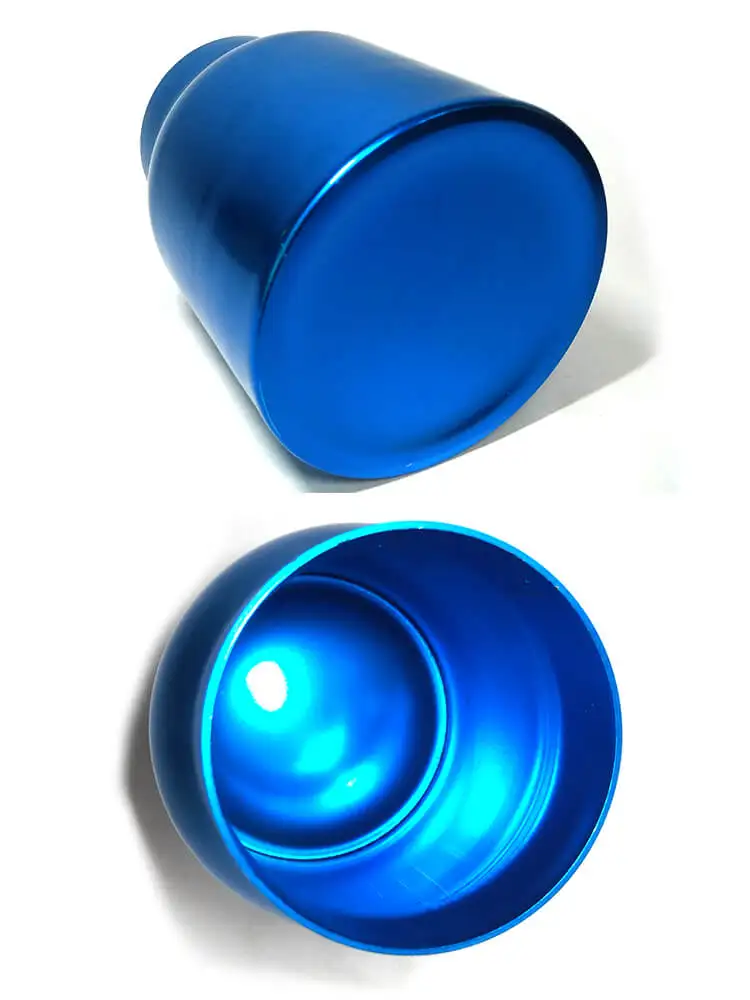

Densen customized aluminum alloy casting precision machining lathing milling polishing aluminum die casting machine metal parts

Application | Well Drilling machinery |

Processing | Investment casting |

Material | Cast steel ;stainless steel (304/316/304L);cast iron |

Tolernace | Controlled by ISO 8006 CT4-6 |

Design Support | Pro-E, UG,SolidWorks,AutoCad, PDF |

Quality Control | Material, Dimension,Performance,inside defects,Balance test |

Standard | ASTM,DIN,JIS,ISO,GB standards |

Products show:

Declaration:

Products shown herein are made to the requirements of specific customers and are illustrative of the types of manufacturing capabilities available within Densen group of companies.

Our policy is that none of these products will be sold to 3rd parties without written consent of the customers to whom the tooling, design and specifications belong.

Process | Material Grade | Weight range | Application |

General machining CNC machining Precision machining Super finishing | Steel, iron, alloy, non-ferrous metals, rare metals and etc. | From 0.1Kg to 100 ton | Aircraft industry Hydraulic electrogenerating Wind power, Tooling, Metallurgy , mine industry etc. |

Standard sea-worthy export packing

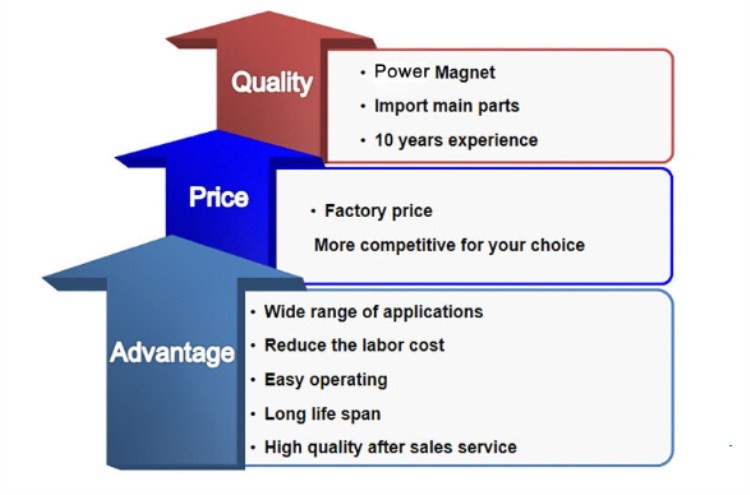

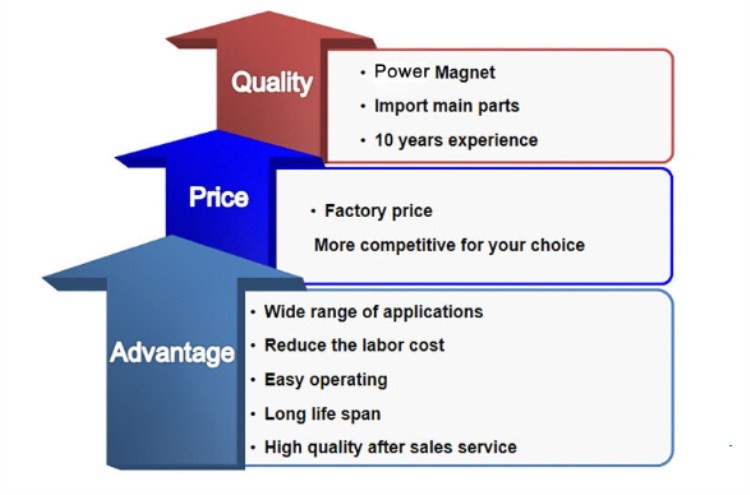

With well-equipped professional engineers and strong technical ability, our company has been in this field for 10 years.

1.We cooperate with superior suppliers (Nord &Schneider)to ensure the quality.

2.Tests of materials are freely checked for the required quality of the equipment before packing.

3.Engineers are always available to service for machinery commissioning overseas, which is not only after sales service support, but also technology support .

4."Keep Improving, Pursuing Excellence" would be kept forever.

Densen customized aluminum alloy casting precision machining lathing milling polishing aluminum die casting machine metal parts

Application | Well Drilling machinery |

Processing | Investment casting |

Material | Cast steel ;stainless steel (304/316/304L);cast iron |

Tolernace | Controlled by ISO 8006 CT4-6 |

Design Support | Pro-E, UG,SolidWorks,AutoCad, PDF |

Quality Control | Material, Dimension,Performance,inside defects,Balance test |

Standard | ASTM,DIN,JIS,ISO,GB standards |

Products show:

Declaration:

Products shown herein are made to the requirements of specific customers and are illustrative of the types of manufacturing capabilities available within Densen group of companies.

Our policy is that none of these products will be sold to 3rd parties without written consent of the customers to whom the tooling, design and specifications belong.

Process | Material Grade | Weight range | Application |

General machining CNC machining Precision machining Super finishing | Steel, iron, alloy, non-ferrous metals, rare metals and etc. | From 0.1Kg to 100 ton | Aircraft industry Hydraulic electrogenerating Wind power, Tooling, Metallurgy , mine industry etc. |

Standard sea-worthy export packing

With well-equipped professional engineers and strong technical ability, our company has been in this field for 10 years.

1.We cooperate with superior suppliers (Nord &Schneider)to ensure the quality.

2.Tests of materials are freely checked for the required quality of the equipment before packing.

3.Engineers are always available to service for machinery commissioning overseas, which is not only after sales service support, but also technology support .

4."Keep Improving, Pursuing Excellence" would be kept forever.

| | Floor 21, Block B, Fortune Building, No. 18 Xinghua Bei Street , Tiexi District, Shenyang, 110025, China. |

| | 86 15541524932 |

| | contact@sydensen.com |