- Home

- Factories

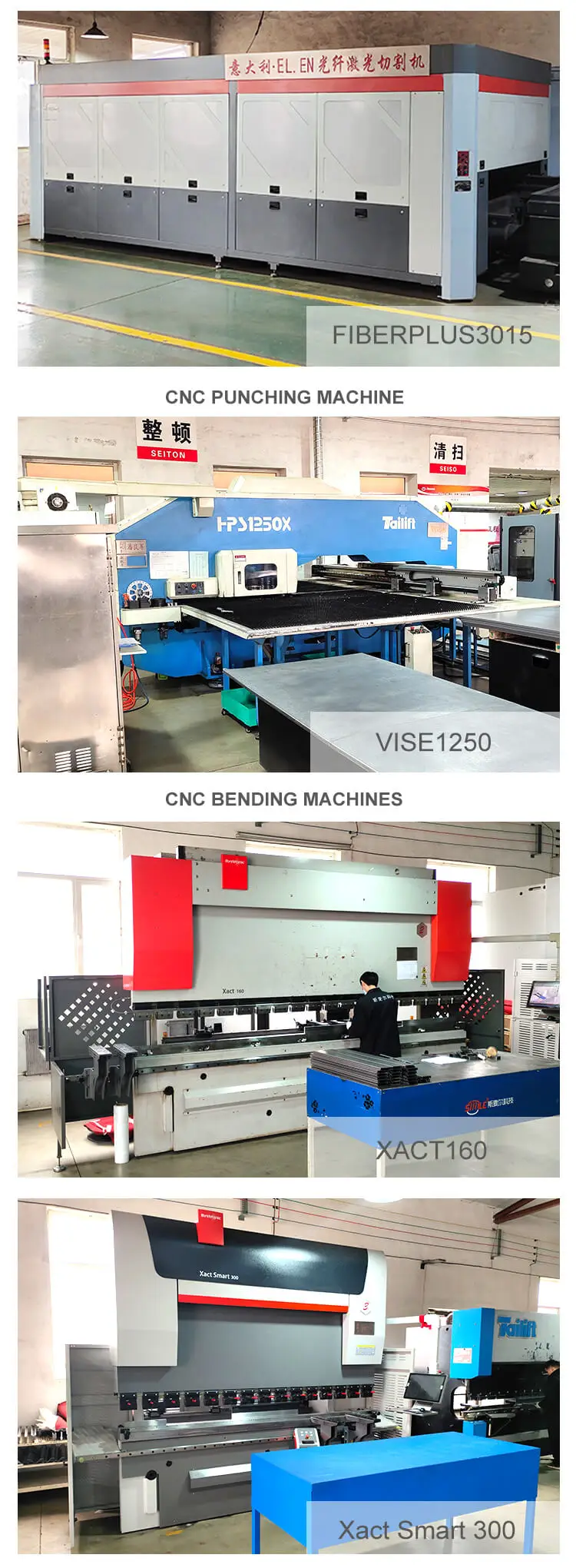

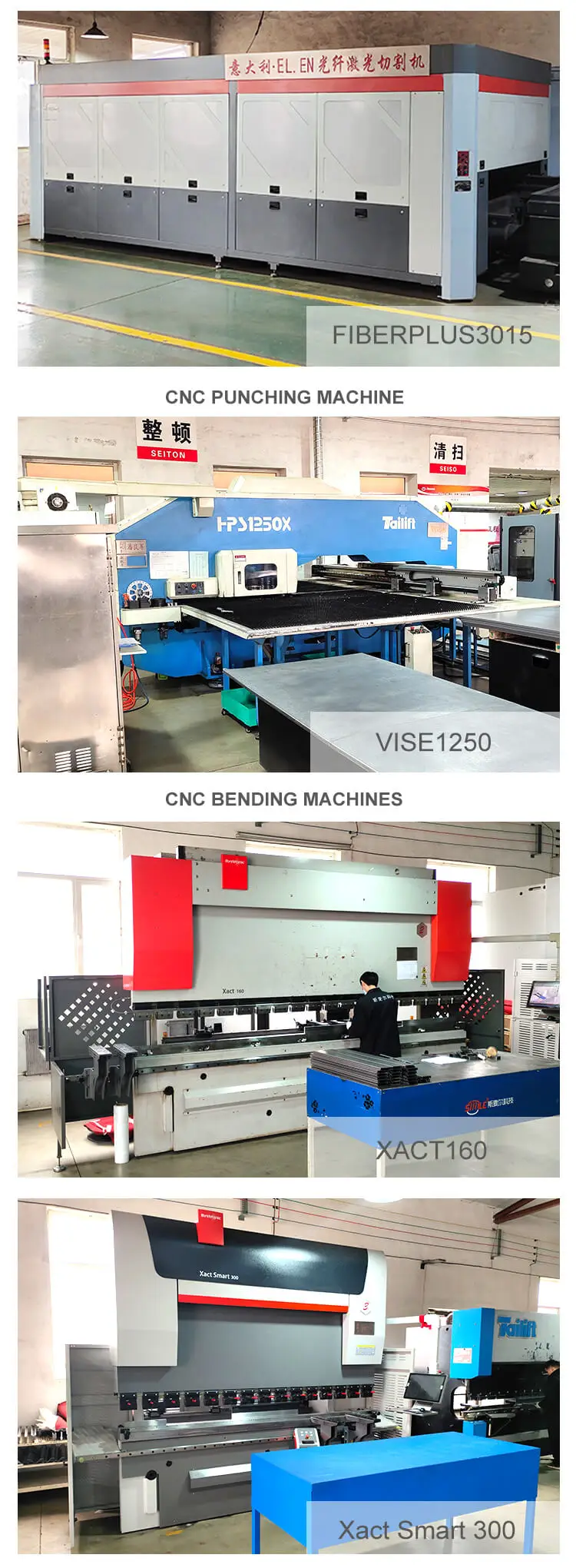

- Processes

- Products

- News

- Download

- Contact Us

| Molded parts: | |

|---|---|

| Sheet thickness: | |

| Surface Treatment: | |

| Proofing cycle: | |

| Application field: | |

| Availability: | |

| Quantity: | |

customized

OEM

Type | CASE |

Application | Communication, industry, electrical |

Material | steel ;stainless steel (304/316/304L) |

Tolernace | Controlled by ISO 8006 CT4-6 |

Design Support | Pro-E, UG,SolidWorks,AutoCad, PDF |

Quality Control | Material, Dimension,Performance,inside defects,Balance test |

Standard | ASTM,DIN,JIS,ISO,GB standards |

Products show:

| Product Name | Sheet metal automatic vending automatic teller machine enclosure | ||

| Sheet metal material | Q235 | ||

| Sheet thickness | 1.5mm | ||

| Molded parts | Cabinet | ||

| Surface treatment | Spray molding | ||

| Proofing cycle | 4-7 day | ||

| Processing cycle | 8-15 day | ||

| Application field | Communication, industry, electrical | ||

| Product Name | Self-service integrated circuit making machine enclosure shell | ||

| Sheet metal material | Q235 | ||

| Sheet thickness | 1.5mm | ||

| Molded parts | Cabinet | ||

| Surface treatment | Spray molding | ||

| Proofing cycle | 4-7 day | ||

| Processing cycle | 8-15 day | ||

| Application field | Communication, Industry, Electricity | ||

Declaration:

Products shown herein are made to the requirements of specific customers and are illustrative of the types of manufacturing capabilities available within Densen group of companies.

Our policy is that none of these products will be sold to 3rd parties without written consent of the customers to whom the tooling, design and specifications belong.

Type | CASE |

Application | Communication, industry, electrical |

Material | steel ;stainless steel (304/316/304L) |

Tolernace | Controlled by ISO 8006 CT4-6 |

Design Support | Pro-E, UG,SolidWorks,AutoCad, PDF |

Quality Control | Material, Dimension,Performance,inside defects,Balance test |

Standard | ASTM,DIN,JIS,ISO,GB standards |

Products show:

| Product Name | Sheet metal automatic vending automatic teller machine enclosure | ||

| Sheet metal material | Q235 | ||

| Sheet thickness | 1.5mm | ||

| Molded parts | Cabinet | ||

| Surface treatment | Spray molding | ||

| Proofing cycle | 4-7 day | ||

| Processing cycle | 8-15 day | ||

| Application field | Communication, industry, electrical | ||

| Product Name | Self-service integrated circuit making machine enclosure shell | ||

| Sheet metal material | Q235 | ||

| Sheet thickness | 1.5mm | ||

| Molded parts | Cabinet | ||

| Surface treatment | Spray molding | ||

| Proofing cycle | 4-7 day | ||

| Processing cycle | 8-15 day | ||

| Application field | Communication, Industry, Electricity | ||

Declaration:

Products shown herein are made to the requirements of specific customers and are illustrative of the types of manufacturing capabilities available within Densen group of companies.

Our policy is that none of these products will be sold to 3rd parties without written consent of the customers to whom the tooling, design and specifications belong.

| | Floor 21, Block B, Fortune Building, No. 18 Xinghua Bei Street , Tiexi District, Shenyang, 110025, China. |

| | 86 15541524932 |

| | contact@sydensen.com |