- Home

- Factories

- Processes

- Products

- News

- Download

- Contact Us

| Dimensions: | |

|---|---|

| Material: | |

| Product Name: | |

| Process: | |

| Weight: | |

| Availability: | |

| Quantity: | |

Densen customized

DS

Description | investment casting parts |

Type | OEM |

Application | Industry system |

Processing | Investment casting |

Material | Cast steel ;stainless steel (304/316/304L);cast iron |

| Weight Ranges | 0.05-100kg |

Tolernace | Controlled by ISO 8006 CT4-6 |

Design Support | Pro-E, UG,SolidWorks,AutoCad, PDF |

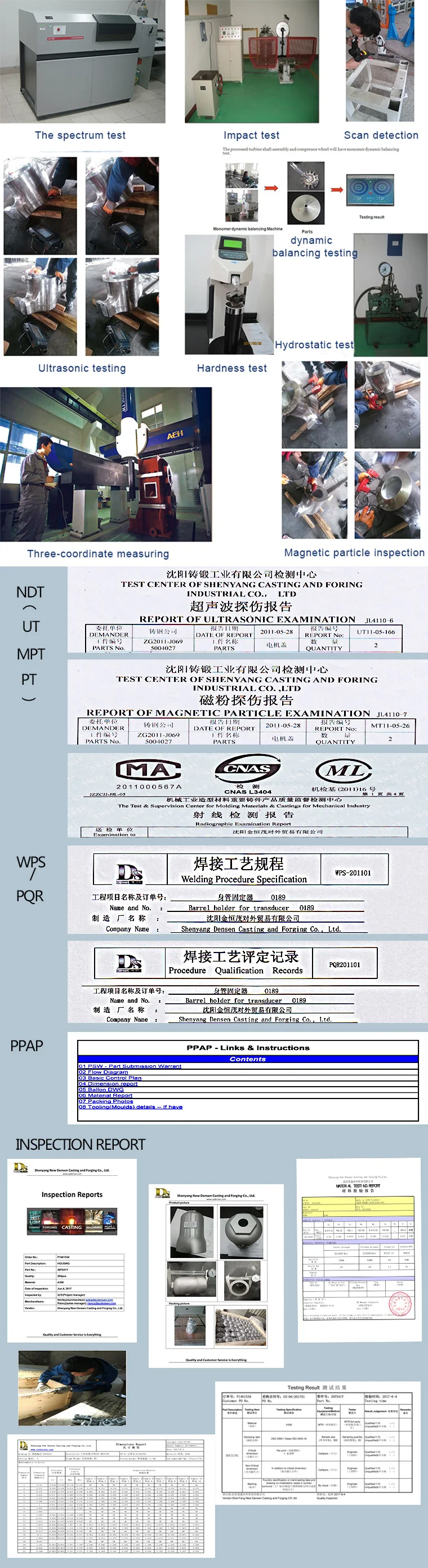

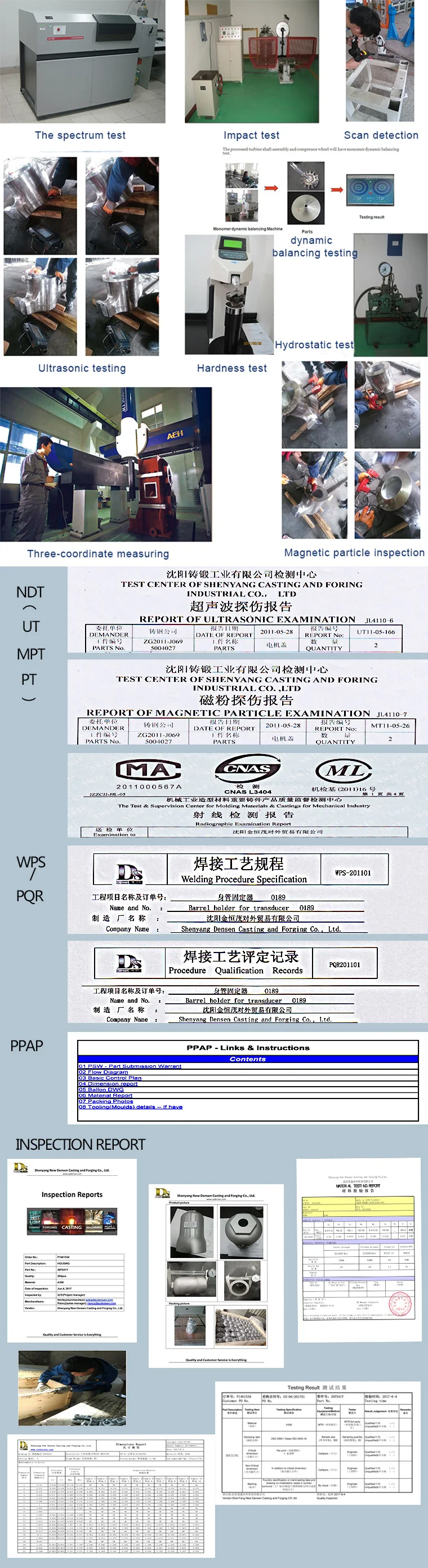

Quality Control | Material, Dimension,Performance,inside defects,Balance test |

Standard | ASTM,DIN,JIS,ISO,GB standards |

Products show:

Declaration:

Products shown herein are made to the requirements of specific customers and are illustrative of the types of manufacturing capabilities available within Densen group of companies.

Our policy is that none of these products will be sold to 3rd parties without written consent of the customers to whom the tooling, design and specifications belong.

New Densen's Profile

Shenyang New Densen Casting and Forging Co., Ltd. is the specialist in the supply of customized metal components and service, which works closely with its 9 sister factories in Shenyang Densen Group of Companies and over 30 sub-contractors, mainly in charge of communication, documentation and logistic work, quality supervision and inspection for its suppliers and customers.

New Densen’s Features

1. Our key products include

Casting, forging, stamping, machining, welding and fabrication components and solutions made to specific customer requirements.

2. Material we handled include:

All kind of iron, steel, non-ferrous as per customer specific standards and all international standard.

3. We supply components ranging:

From 0.01 Kg to 240 Tons.

4. Company history we have:

25 years manufacturing experiences (since 1992).

9 years direct export experiences (since 2008).

5. Global customers we have been in cooperation are:

More than 100 companies. Of which 50%+ are from Fortune 500 list.

6. New Densen’s products are used in a wide variety of application and industry sectors. Such as:

![]()

7. Quality assurance we can offer:

All our factories are awarded certification of ISO9001:2008 and TS16949.

3rd party production supervision and double quality inspection offered by New Densen

3rd party trade assurance from Alibaba available

Description | investment casting parts |

Type | OEM |

Application | Industry system |

Processing | Investment casting |

Material | Cast steel ;stainless steel (304/316/304L);cast iron |

| Weight Ranges | 0.05-100kg |

Tolernace | Controlled by ISO 8006 CT4-6 |

Design Support | Pro-E, UG,SolidWorks,AutoCad, PDF |

Quality Control | Material, Dimension,Performance,inside defects,Balance test |

Standard | ASTM,DIN,JIS,ISO,GB standards |

Products show:

Declaration:

Products shown herein are made to the requirements of specific customers and are illustrative of the types of manufacturing capabilities available within Densen group of companies.

Our policy is that none of these products will be sold to 3rd parties without written consent of the customers to whom the tooling, design and specifications belong.

New Densen's Profile

Shenyang New Densen Casting and Forging Co., Ltd. is the specialist in the supply of customized metal components and service, which works closely with its 9 sister factories in Shenyang Densen Group of Companies and over 30 sub-contractors, mainly in charge of communication, documentation and logistic work, quality supervision and inspection for its suppliers and customers.

New Densen’s Features

1. Our key products include

Casting, forging, stamping, machining, welding and fabrication components and solutions made to specific customer requirements.

2. Material we handled include:

All kind of iron, steel, non-ferrous as per customer specific standards and all international standard.

3. We supply components ranging:

From 0.01 Kg to 240 Tons.

4. Company history we have:

25 years manufacturing experiences (since 1992).

9 years direct export experiences (since 2008).

5. Global customers we have been in cooperation are:

More than 100 companies. Of which 50%+ are from Fortune 500 list.

6. New Densen’s products are used in a wide variety of application and industry sectors. Such as:

![]()

7. Quality assurance we can offer:

All our factories are awarded certification of ISO9001:2008 and TS16949.

3rd party production supervision and double quality inspection offered by New Densen

3rd party trade assurance from Alibaba available

| | Floor 21, Block B, Fortune Building, No. 18 Xinghua Bei Street , Tiexi District, Shenyang, 110025, China. |

| | 86 15541524932 |

| | contact@sydensen.com |