- Home

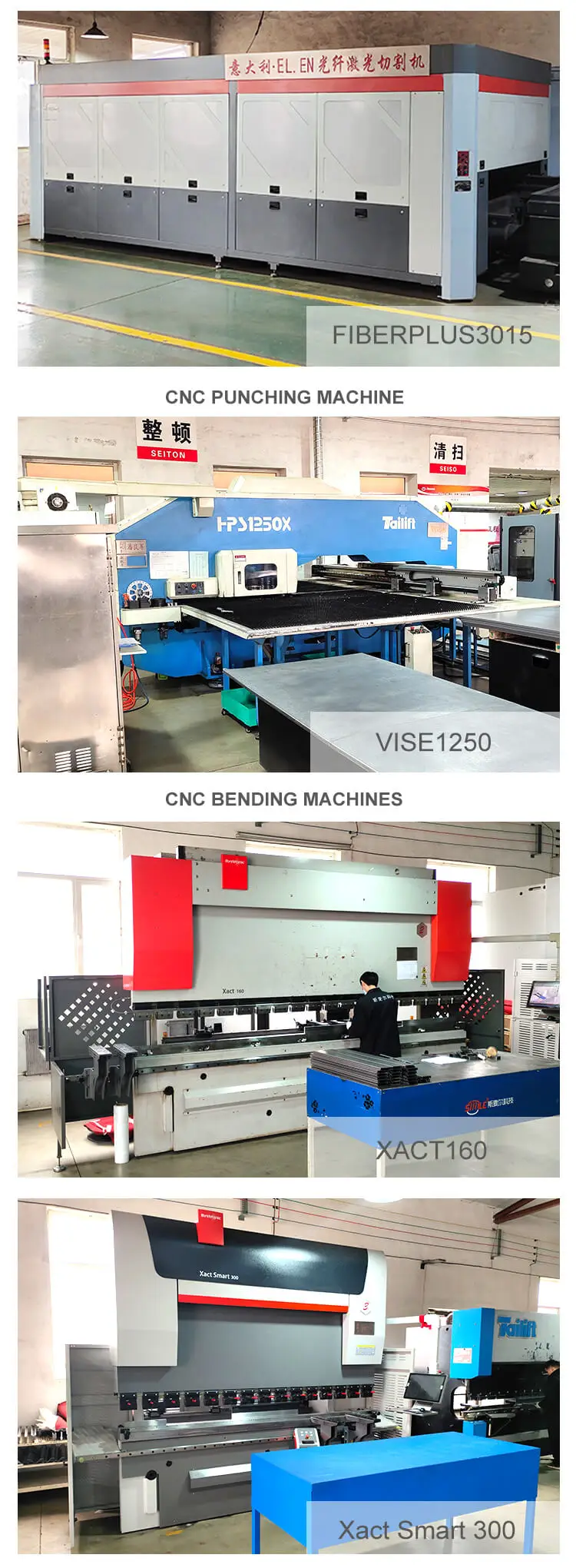

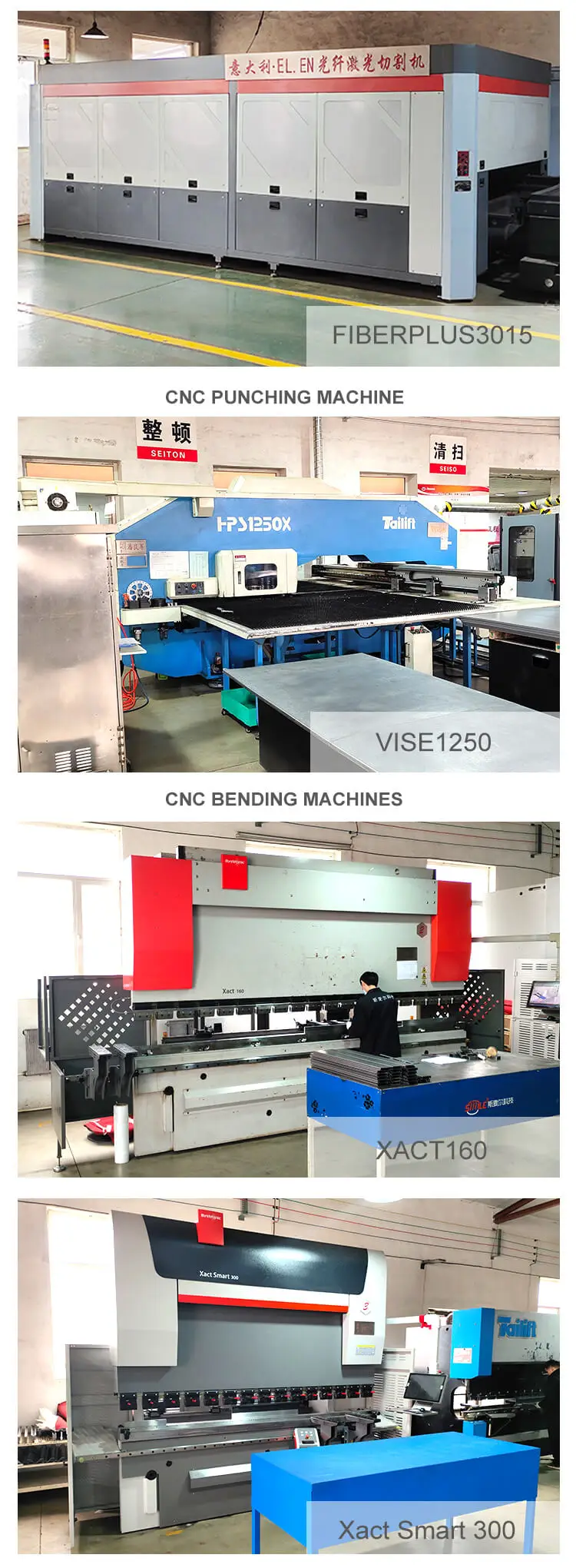

- Factories

- Processes

- Products

- News

- Download

- Contact Us

| Product Name: | |

|---|---|

| Material: | |

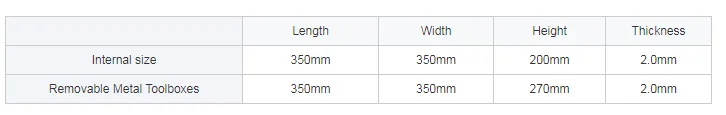

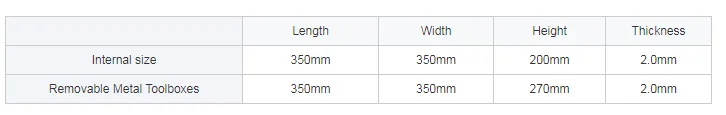

| Size: | |

| Surface Treatment: | |

| Thickness: | |

| Availability: | |

| Quantity: | |

DS customized

DS

Type | Removable Metal Tool Boxes |

Material | Stainless steel |

Tolernace | Controlled by ISO 8006 CT4-6 |

Design Support | Pro-E, UG,SolidWorks,AutoCad, PDF |

Quality Control | Material, Dimension,Performance,inside defects,Balance test |

Standard | ASTM,DIN,JIS,ISO,GB standards |

Products show:

Movable metal tool box is made of Q235 metal material, with a thickness of 2.0mm and a gray matte waterproof spraying on the surface. Different materials and thickness can also be chosen according to different demands. The movable metal tool box is widely used in the assembly workshop of the factory. Tools can be placed inside the tool box to ensure that workers sit on the tool box without damage.

Products shown herein are made to the requirements of specific customers and are illustrative of the types of manufacturing capabilities available within Densen group of companies.

Our policy is that none of these products will be sold to 3rd parties without written consent of the customers to whom the tooling, design and specifications belong.

Type | Removable Metal Tool Boxes |

Material | Stainless steel |

Tolernace | Controlled by ISO 8006 CT4-6 |

Design Support | Pro-E, UG,SolidWorks,AutoCad, PDF |

Quality Control | Material, Dimension,Performance,inside defects,Balance test |

Standard | ASTM,DIN,JIS,ISO,GB standards |

Products show:

Movable metal tool box is made of Q235 metal material, with a thickness of 2.0mm and a gray matte waterproof spraying on the surface. Different materials and thickness can also be chosen according to different demands. The movable metal tool box is widely used in the assembly workshop of the factory. Tools can be placed inside the tool box to ensure that workers sit on the tool box without damage.

Products shown herein are made to the requirements of specific customers and are illustrative of the types of manufacturing capabilities available within Densen group of companies.

Our policy is that none of these products will be sold to 3rd parties without written consent of the customers to whom the tooling, design and specifications belong.

| | Floor 21, Block B, Fortune Building, No. 18 Xinghua Bei Street , Tiexi District, Shenyang, 110025, China. |

| | 86 15541524932 |

| | contact@sydensen.com |