- Home

- Factories

- Processes

- Products

- News

- Download

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

MAR-0015

DS

Densen Customized China Manufacturer Casting Hydrofoil Impeller

Process | sand casting , die casting,centrifugal casting, Investment Casting,lost foam casting |

Material | Copper, iron, aluminum, tin, ,lead, gray pig iron, nodular cast iron malleable cast iron, cast steel, brass, tin bronze, aluminium alloy |

Material Grade | GB, ASTM , AISI , DIN , BS, JIS, NF,ISO |

Weight | 0.01kg-1000kg |

Accuracy | class CT7~CT10 |

Surface Roughness | up to Ra1.6~Ra6.3 |

Applied software | ProE (.igs , .stp) , Auto CAD , PDF, Jpeg, Jpg, Png |

Production capacity | more than 1500MT per year |

Heat Treatment | anneal,quenching,normalizing,carburizing, polishing, plating, painting |

Machining Equipment | CNC center , CNC machines, turning machines, drilling machines , milling machines, grinding machines |

Measuring Tool | CMM , vernier caliper, depth caliper, micrometer, pin gauge, thread gauge , height gauge |

QC system | Own inspection department and guage,100 inspection before delivery

|

MOQ | 500kg |

Lead Time | sample fast , lot production depends on customers' request |

Certification | ISO9001 |

Payment Terms | T/T , L/C, D/P , D/A |

Shipment Terms | FOB , CFR, CIF |

ABOUT US:

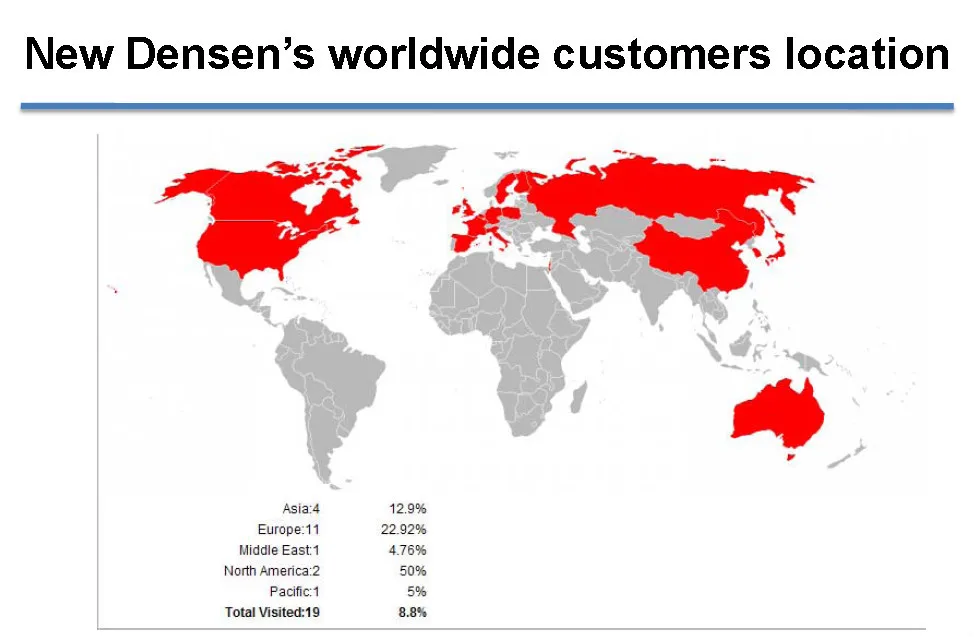

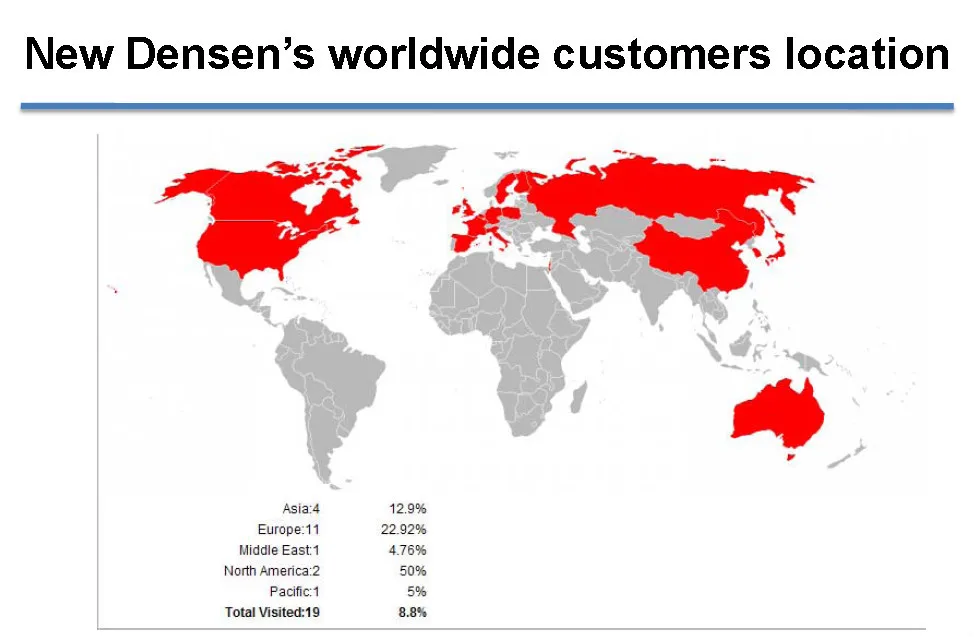

With the help of over 20 years manufacturing experiences in the field of oil & gas, mining, power generation, transportation industries, Shenyang New Densen Casting and Forging Co., Ltd. and its 15 factories would like to help our worldwide customers to supply the best quality mechanical products with the most competitive prices.

The product single weight could be from 0.01KGS TO100,000KGS. The processes could be casting, forging, stamping, machining, fabrication and assembly. The material could be various steel, iron and non-ferrous.

All our factories are ISO 9001 certified. Some of them were awarded by ISO/TS16949, PED, etc. We also could provide RT, UT, MPI, WPS&PQR, etc. as per request.

Densen will not only manufacture and source products for our customers, but also provide technical support, production all-time supervision and quality track service. Special request products available upon request

Just inform us what you are looking for, our professional team will help you to finish the other work.

To be one-stop sourcing platform for our customers is Densen’s principle all the time.

FAQ:

Q1:How long shall we get the quotation?

Processing time for Enquiries :1-3 days

Q2:What is your payment term?

Payment term:

1)Pattern and tooling: 50% prepaid as order deposit; balance 50% paid within 10 days after samples approved.

2)Samples: 50% prepaid as order deposit; balance 50% paid within 10 days after samples approved.

3)Products: 30% prepaid as order deposit;70% paid before EX-work.

Q3:Will we have the property of the tooling?

Yes,tooling's cost is one-time charge,the property of toolings will be yours after pay off all the charges.

Q4:What shall we do if the quality is not meet our requirement?

If it is true after we re-test,we can repay the payment or re-produce until it reach the quality

1. Quality guarantee

• Chemical checking

• Mechanical testing after heat treatment

• Dimension inspected

2. Quality document

• Full Q.A document as per client request

3.Packing and Shipping

• Standard export package(carton/wooden case/pallet)

• Accept FOB,FAS,CNF,CIF door to door etc. or customer

designated shipping agent.

4.Service

• Drawing: we can translate your original drawing, offer

best suggestion on design.

• Quality: we have full set quality control system to

guarantee the best quality.

5.Inspection

• Inspect in house, all our products must be checked 3 times before packing.

• Third party inspection available upon requirement

Welcome to visit Densen factory if you are interested in us!!

Our products manufactured according to standard schedule strictly, with stable quality and timely delivery.

Hope our manufacture and service could benefit you some day in near future!

If you are looking for this kind of products right now , please do not hesitate to contact us by any of below methods:

Densen Customized China Manufacturer Casting Hydrofoil Impeller

Process | sand casting , die casting,centrifugal casting, Investment Casting,lost foam casting |

Material | Copper, iron, aluminum, tin, ,lead, gray pig iron, nodular cast iron malleable cast iron, cast steel, brass, tin bronze, aluminium alloy |

Material Grade | GB, ASTM , AISI , DIN , BS, JIS, NF,ISO |

Weight | 0.01kg-1000kg |

Accuracy | class CT7~CT10 |

Surface Roughness | up to Ra1.6~Ra6.3 |

Applied software | ProE (.igs , .stp) , Auto CAD , PDF, Jpeg, Jpg, Png |

Production capacity | more than 1500MT per year |

Heat Treatment | anneal,quenching,normalizing,carburizing, polishing, plating, painting |

Machining Equipment | CNC center , CNC machines, turning machines, drilling machines , milling machines, grinding machines |

Measuring Tool | CMM , vernier caliper, depth caliper, micrometer, pin gauge, thread gauge , height gauge |

QC system | Own inspection department and guage,100 inspection before delivery

|

MOQ | 500kg |

Lead Time | sample fast , lot production depends on customers' request |

Certification | ISO9001 |

Payment Terms | T/T , L/C, D/P , D/A |

Shipment Terms | FOB , CFR, CIF |

ABOUT US:

With the help of over 20 years manufacturing experiences in the field of oil & gas, mining, power generation, transportation industries, Shenyang New Densen Casting and Forging Co., Ltd. and its 15 factories would like to help our worldwide customers to supply the best quality mechanical products with the most competitive prices.

The product single weight could be from 0.01KGS TO100,000KGS. The processes could be casting, forging, stamping, machining, fabrication and assembly. The material could be various steel, iron and non-ferrous.

All our factories are ISO 9001 certified. Some of them were awarded by ISO/TS16949, PED, etc. We also could provide RT, UT, MPI, WPS&PQR, etc. as per request.

Densen will not only manufacture and source products for our customers, but also provide technical support, production all-time supervision and quality track service. Special request products available upon request

Just inform us what you are looking for, our professional team will help you to finish the other work.

To be one-stop sourcing platform for our customers is Densen’s principle all the time.

FAQ:

Q1:How long shall we get the quotation?

Processing time for Enquiries :1-3 days

Q2:What is your payment term?

Payment term:

1)Pattern and tooling: 50% prepaid as order deposit; balance 50% paid within 10 days after samples approved.

2)Samples: 50% prepaid as order deposit; balance 50% paid within 10 days after samples approved.

3)Products: 30% prepaid as order deposit;70% paid before EX-work.

Q3:Will we have the property of the tooling?

Yes,tooling's cost is one-time charge,the property of toolings will be yours after pay off all the charges.

Q4:What shall we do if the quality is not meet our requirement?

If it is true after we re-test,we can repay the payment or re-produce until it reach the quality

1. Quality guarantee

• Chemical checking

• Mechanical testing after heat treatment

• Dimension inspected

2. Quality document

• Full Q.A document as per client request

3.Packing and Shipping

• Standard export package(carton/wooden case/pallet)

• Accept FOB,FAS,CNF,CIF door to door etc. or customer

designated shipping agent.

4.Service

• Drawing: we can translate your original drawing, offer

best suggestion on design.

• Quality: we have full set quality control system to

guarantee the best quality.

5.Inspection

• Inspect in house, all our products must be checked 3 times before packing.

• Third party inspection available upon requirement

Welcome to visit Densen factory if you are interested in us!!

Our products manufactured according to standard schedule strictly, with stable quality and timely delivery.

Hope our manufacture and service could benefit you some day in near future!

If you are looking for this kind of products right now , please do not hesitate to contact us by any of below methods:

| | Floor 21, Block B, Fortune Building, No. 18 Xinghua Bei Street , Tiexi District, Shenyang, 110025, China. |

| | 86 15541524932 |

| | contact@sydensen.com |