- Home

- Factories

- Processes

- Products

- News

- Download

- Contact Us

| Quantity: | |

|---|---|

Non-standard

DS

Iron / Steel / Aluminum

0.01kg-10t

Cast Iron / Steel / Aluminum

Painting/sand blasting/oiled

avaliable

customized

static balance test

reasonalbe

Industry, Machinery Parts, Construction Industry,

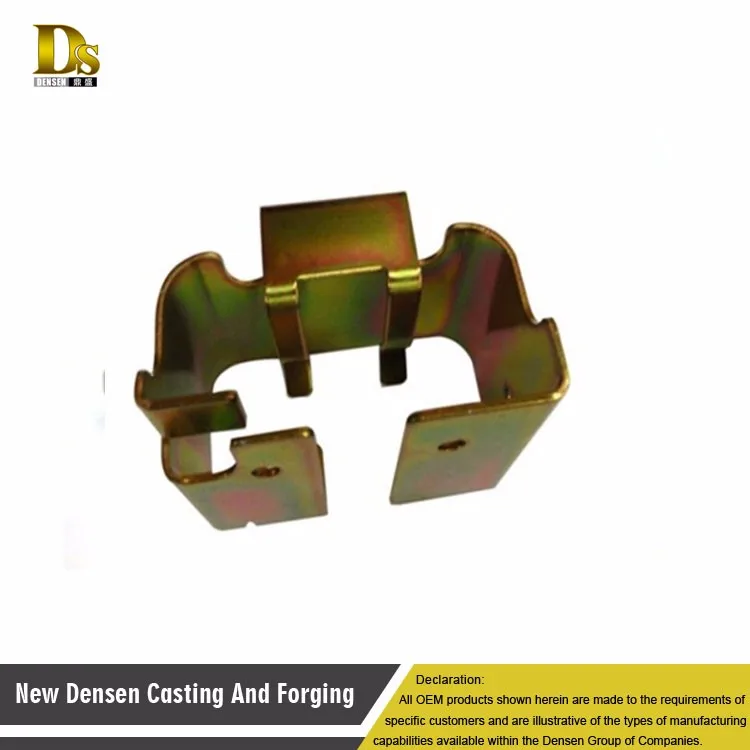

Customized Stamping and welding machine parts CNC OEM punched parts

We are OEM Manufacture which professionally do Investment Casting & Machining for years!!!

| process | Investment casting,sand casting,ESR casting,Die casting,stamping |

| Material | Iron:Grey iron, Ductile iron Steel:Carbon steel, Alloy steel,Stainless steel Nonferrous metal:Bronze, Brass, Al, Zinc, Ti, etc. |

| Material Grade | GB, ASTM , AISI , DIN , BS, JIS, NF,ISO |

| Surface Roughness | up to Ra1.6~Ra6.3 |

| Production capacity | more than 1500 kilograms per year |

| Heat Treatment | anneal,quenching,normalizing,carburizing, polishing, plating, painting |

| Machining Equipment | CNC center , CNC machines, turning machines, drilling machines , milling machines, grinding machines |

| QC system | Own inspection department and guage,100 inspection before delivery |

| MOQ | 100 Kilogram/Kilograms |

| Lead Time | sample fast , lot production depends on customers' request |

| Certification | ISO9001,EN 3.1 B |

| Payment Terms | T/T , L/C, D/P , D/A |

| Shipment Terms | FOB , CFR, CIF |

we can also design packaging as clients requirement !!!

Packing Details : Wooden case,Plywood case,PE film,etc.up to customer's request

Delivery Details : Shipped in 30 days after payment

Our Workshop

Our Warehouse

Our Team

| Low MOQ | We are always ready for providing the sample and producing some small orders, in order to meet the business well. | ||

| OEM Accepted | We can make the products with the client's demand standard or the custom requirement. | ||

| Complete Service | We are always ready to hear from you, be responding to your inquiry immediately. Our trade manager is always online for you. | ||

| High Quality | We have strict quality control system and amounts of testing equipment for different kind of castings, such as size, hardness, chemical components, Roughness, etc. | ||

| Quality Assurance | we promise that the minimum period quality assurance is one year. If the products have any problem on quality within this period, we all provide exchange service. | ||

| Competitive Prices | We are the foundry, having our own manufacturing workshop and providing the straight factory price and service to our customer. | ||

1. Quality guarantee

• Chemical checking

• Mechanical testing after heat treatment

• Dimension inspected

2. Quality document

• Full Q.A document as per client request

3.Packing and Shipping

• Standard export package(carton/wooden case/pallet)

• Accept FOB,FAS,CNF,CIF door to door etc. or customer

designated shipping agent.

4.Service

• Drawing: we can translate your original drawing, offer

best suggestion on design.

• Quality: we have full set quality control system to guarantee the best quality.

5.Inspection

•Inspect in house, all our products must be checked 3 times before packing.

• Third party inspection available upon requirement

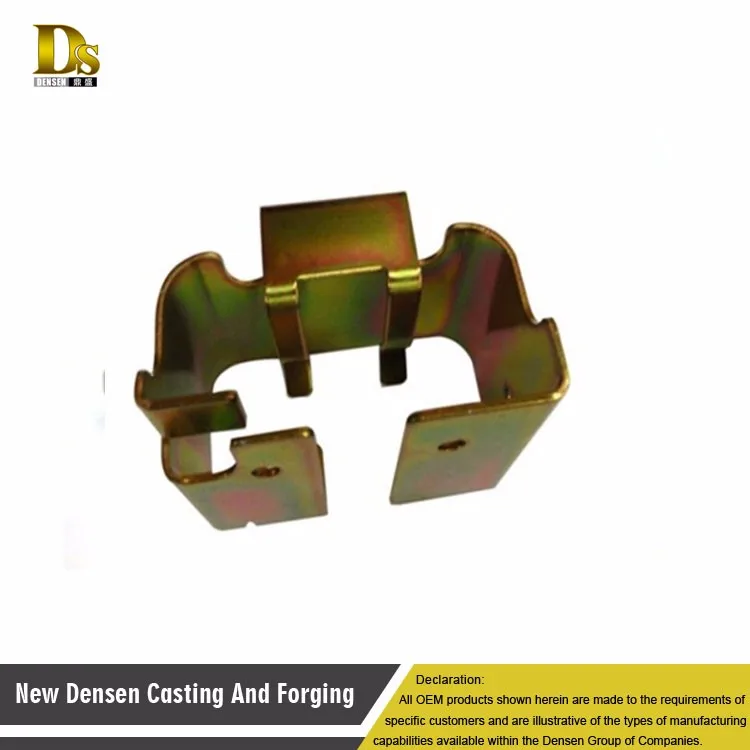

Customized Stamping and welding machine parts CNC OEM punched parts

We are OEM Manufacture which professionally do Investment Casting & Machining for years!!!

| process | Investment casting,sand casting,ESR casting,Die casting,stamping |

| Material | Iron:Grey iron, Ductile iron Steel:Carbon steel, Alloy steel,Stainless steel Nonferrous metal:Bronze, Brass, Al, Zinc, Ti, etc. |

| Material Grade | GB, ASTM , AISI , DIN , BS, JIS, NF,ISO |

| Surface Roughness | up to Ra1.6~Ra6.3 |

| Production capacity | more than 1500 kilograms per year |

| Heat Treatment | anneal,quenching,normalizing,carburizing, polishing, plating, painting |

| Machining Equipment | CNC center , CNC machines, turning machines, drilling machines , milling machines, grinding machines |

| QC system | Own inspection department and guage,100 inspection before delivery |

| MOQ | 100 Kilogram/Kilograms |

| Lead Time | sample fast , lot production depends on customers' request |

| Certification | ISO9001,EN 3.1 B |

| Payment Terms | T/T , L/C, D/P , D/A |

| Shipment Terms | FOB , CFR, CIF |

we can also design packaging as clients requirement !!!

Packing Details : Wooden case,Plywood case,PE film,etc.up to customer's request

Delivery Details : Shipped in 30 days after payment

Our Workshop

Our Warehouse

Our Team

| Low MOQ | We are always ready for providing the sample and producing some small orders, in order to meet the business well. | ||

| OEM Accepted | We can make the products with the client's demand standard or the custom requirement. | ||

| Complete Service | We are always ready to hear from you, be responding to your inquiry immediately. Our trade manager is always online for you. | ||

| High Quality | We have strict quality control system and amounts of testing equipment for different kind of castings, such as size, hardness, chemical components, Roughness, etc. | ||

| Quality Assurance | we promise that the minimum period quality assurance is one year. If the products have any problem on quality within this period, we all provide exchange service. | ||

| Competitive Prices | We are the foundry, having our own manufacturing workshop and providing the straight factory price and service to our customer. | ||

1. Quality guarantee

• Chemical checking

• Mechanical testing after heat treatment

• Dimension inspected

2. Quality document

• Full Q.A document as per client request

3.Packing and Shipping

• Standard export package(carton/wooden case/pallet)

• Accept FOB,FAS,CNF,CIF door to door etc. or customer

designated shipping agent.

4.Service

• Drawing: we can translate your original drawing, offer

best suggestion on design.

• Quality: we have full set quality control system to guarantee the best quality.

5.Inspection

•Inspect in house, all our products must be checked 3 times before packing.

• Third party inspection available upon requirement

| | Floor 21, Block B, Fortune Building, No. 18 Xinghua Bei Street , Tiexi District, Shenyang, 110025, China. |

| | 86 15541524932 |

| | contact@sydensen.com |