- Home

- Factories

- Processes

- Products

- News

- Download

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

DS

| Product name | ISO9001 Lost wax casting investment casting machine parts | ||

| Technology | Clay (green) sand casting, Resin sand casting, Iron based coated sand casting | ||

| Applicable material | Cast steel : carbon cast steel, alloy cast steel, stainless steel etc. Cast iron : gray cast iron , ductile (nodular) cast iron, malleable cast iron etc. Aluminum, bronze etc. | ||

| Material standard | GB, ANSI, BS, DIN, JIS,ASTM,ASME,AISI | ||

| Unit weight | 0.5kg -240tons as per customer design drawing | ||

| Main industries our products in | Oil&gas, agricultural (farm machine), forklift, pipefitting, mining, power, machinery industries, etc. | ||

| Typical products we manufactured & exported | Metal core used for rubber tracks of agriculture tractor, insert blocks, gearbox house&lid used for oil drilling equipment, valve parts, pump parts and pedals, pillow blocks(bearing housing),flight drive plates, plough frames, power clamp cover, power clamp frame, heavy duty wheels etc. | ||

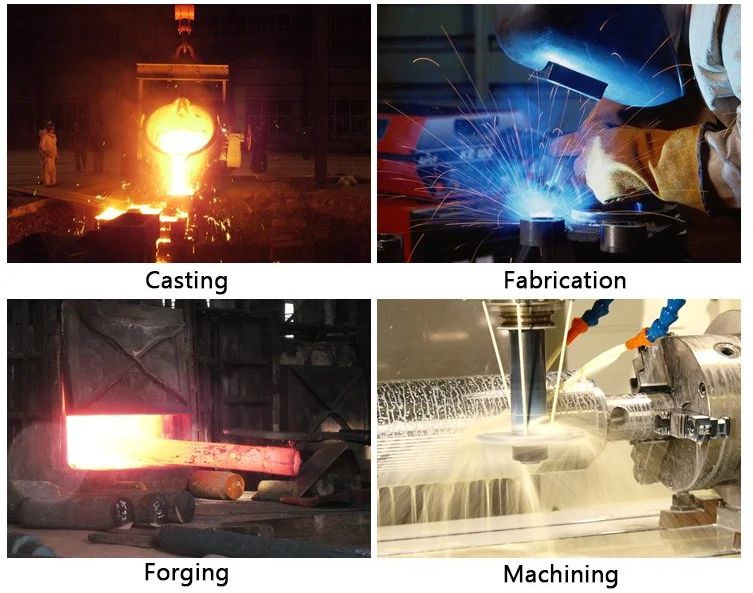

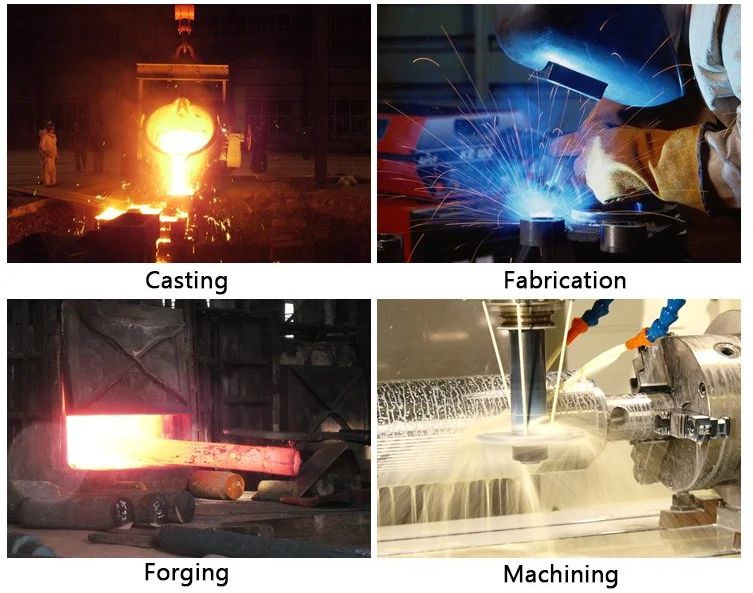

| More casting service we can do | Investment casting, die casting, gravity casting, centrifugal casting ESR casting etc. | ||

| Other manufacture service we can do | forging (free forging, die forging ), stamping, machining, welding fabrication, hydro-forming etc. | ||

| New Densen’s business type | Not only trading company , but have our own foundry (20years), forging factory (7 years) and machining factory (4 years) | ||

| New Densen’s value | supply one-stop sourcing, inspection and technical support Help customers to get high cost performance products locally Worked with institutes, help factories to maintain stable quality Good understanding on overseas standards, strong and responsible QC system, help factories and customers to avoid of non- conformance products | ||

| Customers our products exported to | 70% in Europe and America; 25% in Japan; 5% in other areas. For example: CAD in Italy, BS in Japan, GE in Germany, BT in Canada, FT in USA, and many other companies in USA, UK, Canada, Germany, Israel etc. | ||

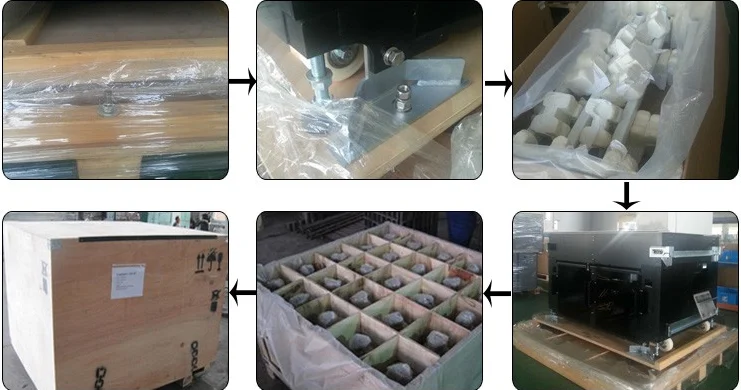

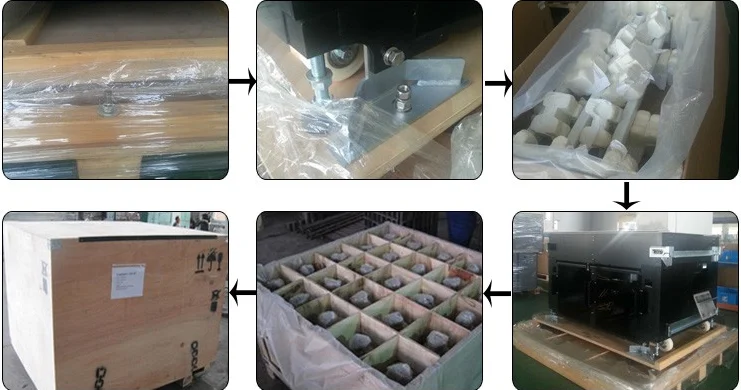

Packing detail:

(1) Standard export packing: carton, crate, pallet ect.

(2) as each customer required.

Frequently Asked Question

1. Are you a manufacturer or a trader?

We are manufacturer AND trader, as we have own factories and also long term friendly cooperated sub-contractors.

That is why we could provide one-stop service to worldwide customers.

2. What can you do for customer ?

One Stop Service

1).Manufacturing and supply various machinery parts.

2). Technical analysis and design

3).Factory audit, on-site production supervision, in-time feedback, pre-shipment quality inspection

3. How could you commit the product quality

1) all our factories were ISO certified.

2) more than 50% of New Densen’s products were sold to worldwide top 500 companies which located in North American,

Western Europe, and Japan.

3) New Densen’s QC engineers will do on-site supervision and before EX-work quality inspection.

New Densen will issue inspection reports for customers’ approval before EX-work. New Densen will be

responsible for its reports and every parts no matter how long sold to customers.

4. What is your payment term?

1) Pattern and tooling: 50% prepaid as order deposit; balance 50% paid within 10 days after samples approved.

2)Sample : 50% prepaid as order deposit; balance 50% paid within 10 days after samples approved.

3)Product: 30% prepaid as order deposit;70% paid before EX-work.

If samples can’t be approved by customers and no need to redo new samples, deposit will be returned to customers.

Welcome customer place order with us through credit system (Trade Assurance), to get alibaba’s credit guarantee.

5. How long shall we get the quotation?

1-3 working days for simple products; 3-5 working days for complicated products

| Product name | ISO9001 Lost wax casting investment casting machine parts | ||

| Technology | Clay (green) sand casting, Resin sand casting, Iron based coated sand casting | ||

| Applicable material | Cast steel : carbon cast steel, alloy cast steel, stainless steel etc. Cast iron : gray cast iron , ductile (nodular) cast iron, malleable cast iron etc. Aluminum, bronze etc. | ||

| Material standard | GB, ANSI, BS, DIN, JIS,ASTM,ASME,AISI | ||

| Unit weight | 0.5kg -240tons as per customer design drawing | ||

| Main industries our products in | Oil&gas, agricultural (farm machine), forklift, pipefitting, mining, power, machinery industries, etc. | ||

| Typical products we manufactured & exported | Metal core used for rubber tracks of agriculture tractor, insert blocks, gearbox house&lid used for oil drilling equipment, valve parts, pump parts and pedals, pillow blocks(bearing housing),flight drive plates, plough frames, power clamp cover, power clamp frame, heavy duty wheels etc. | ||

| More casting service we can do | Investment casting, die casting, gravity casting, centrifugal casting ESR casting etc. | ||

| Other manufacture service we can do | forging (free forging, die forging ), stamping, machining, welding fabrication, hydro-forming etc. | ||

| New Densen’s business type | Not only trading company , but have our own foundry (20years), forging factory (7 years) and machining factory (4 years) | ||

| New Densen’s value | supply one-stop sourcing, inspection and technical support Help customers to get high cost performance products locally Worked with institutes, help factories to maintain stable quality Good understanding on overseas standards, strong and responsible QC system, help factories and customers to avoid of non- conformance products | ||

| Customers our products exported to | 70% in Europe and America; 25% in Japan; 5% in other areas. For example: CAD in Italy, BS in Japan, GE in Germany, BT in Canada, FT in USA, and many other companies in USA, UK, Canada, Germany, Israel etc. | ||

Packing detail:

(1) Standard export packing: carton, crate, pallet ect.

(2) as each customer required.

Frequently Asked Question

1. Are you a manufacturer or a trader?

We are manufacturer AND trader, as we have own factories and also long term friendly cooperated sub-contractors.

That is why we could provide one-stop service to worldwide customers.

2. What can you do for customer ?

One Stop Service

1).Manufacturing and supply various machinery parts.

2). Technical analysis and design

3).Factory audit, on-site production supervision, in-time feedback, pre-shipment quality inspection

3. How could you commit the product quality

1) all our factories were ISO certified.

2) more than 50% of New Densen’s products were sold to worldwide top 500 companies which located in North American,

Western Europe, and Japan.

3) New Densen’s QC engineers will do on-site supervision and before EX-work quality inspection.

New Densen will issue inspection reports for customers’ approval before EX-work. New Densen will be

responsible for its reports and every parts no matter how long sold to customers.

4. What is your payment term?

1) Pattern and tooling: 50% prepaid as order deposit; balance 50% paid within 10 days after samples approved.

2)Sample : 50% prepaid as order deposit; balance 50% paid within 10 days after samples approved.

3)Product: 30% prepaid as order deposit;70% paid before EX-work.

If samples can’t be approved by customers and no need to redo new samples, deposit will be returned to customers.

Welcome customer place order with us through credit system (Trade Assurance), to get alibaba’s credit guarantee.

5. How long shall we get the quotation?

1-3 working days for simple products; 3-5 working days for complicated products

| | Floor 21, Block B, Fortune Building, No. 18 Xinghua Bei Street , Tiexi District, Shenyang, 110025, China. |

| | 86 15541524932 |

| | contact@sydensen.com |