- Home

- Factories

- Processes

- Products

- News

- Download

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

Customized

DS

Eddy Current Separator Recycling Machine for Medical Glass Scraps

Medical Glass Scraps Containing Aluminum and Copper Recycling Machine

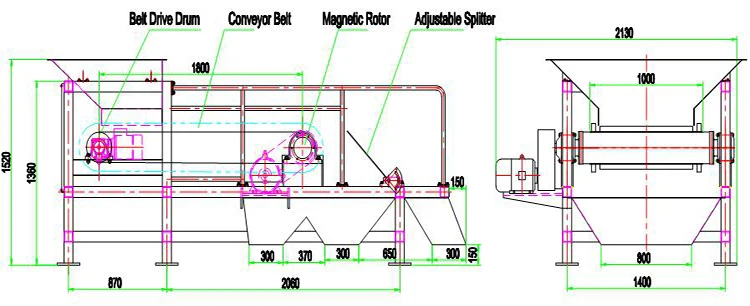

The Magnetic Separating System for waste Scrap is used for medical glass recycling. It can separate iron and nonferrous metals (copper and aluminum)from glass scraps efficiently. This system contains feeder, hooper, conveyor system, vibrator feeder and eddy current separator, etc. And it can be customized to fit the client's needs and will handle multiple tons per hour. Densen also could provide the suitable recycling solutions according to customers’ requirement, such as solid waste sorting line, aluminum recycling line, papermaking waste sorting lines, and scrap steel recycling line.

Description | Eddy Current Separator for Separating Copper Aluminium from meidical glass scraps |

Type | Aluminium copper plastic separator machine |

Application | Foundry, Plastic, E-Waste, Aluminum Industries |

Imported parts | Nord Gear Motor, Sigeling Belt and Schneider Electric parts |

Safety Protective Faclities | Emergency Stop and Open-cover Reset Button |

Design Support | Pro-E, UG,SolidWorks,AutoCad, PDF |

Quality Control | Material, Dimension,Performance |

After-sales Service Provided | Engineers available to service machinery overseas for 1 year |

Products show:

Details:

Workshops

Standard Features and Benefits:

1. the special feature is the eccentric pole system, it is adjustable,

2. compared to concentric pole systems, the eccentric pole system increases the metal yield by 50%.

3. assembled with imported components,

4.advanced smooth systerm. service life of the belt and drum shell is considerably lengthened.

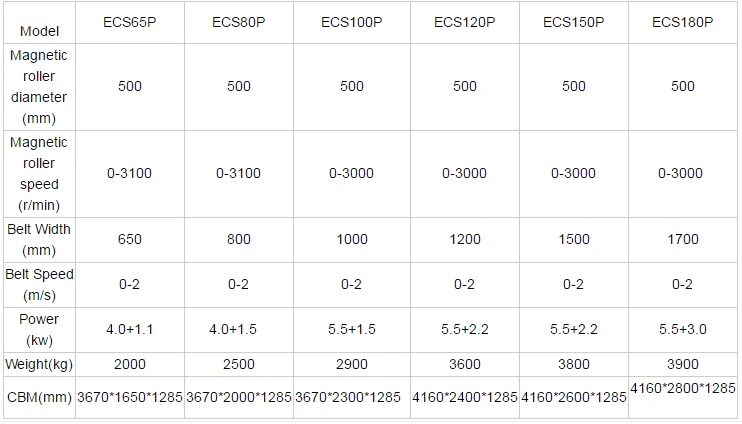

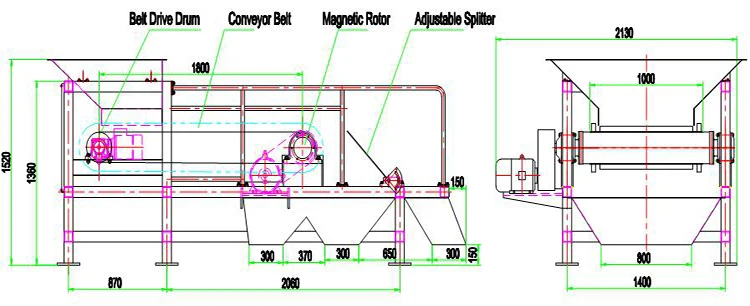

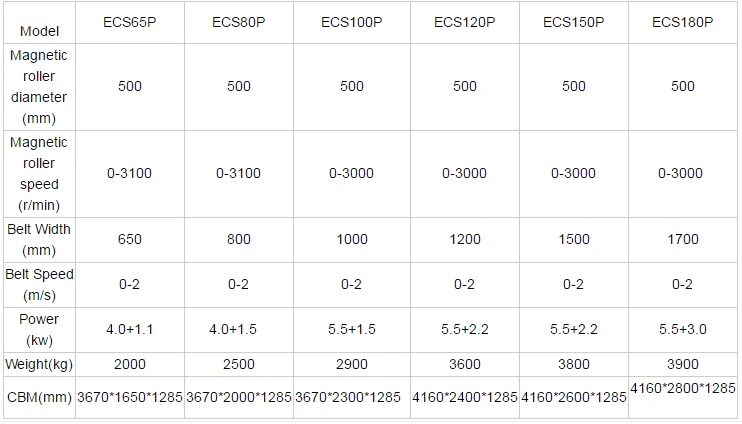

Specification:

The separation process

Our engineers can design drawings or make a recommendationbased on your needs.

Example:

Declaration:

Products shown herein are made to the requirements of specific customers and are illustrative of the types of manufacturing capabilities available within Densen group of companies.

Our policy is that none of these products will be sold to 3rd parties without written consent of the customers to whom the tooling, design and specifications belong.

Our factory is Located in shanyang ,China, which is a professional enterprise producing magnetic series products. Our factory has been focusing on designing and manufacturing magnetic equipment for 12 years since 2006.We are one of the earliest suppliers of magnetic separator and eddy current separator in Asia. Main products are Eddy current separator, magnetic separator, belt magnetic separator, Drum magnetic separator and Grate magnets.

Our Advantage:

1. We have 13 years of professional production experience, and we are one of the earliest manufacturer of eddy current separator in China.

2. We have a technical engineer team with 10 engineers who have more than 25 years of working experience in eddy current separator.

3. In the list of 98 China National fixed appliances dismantling of the plant, there are 55 factories use our equipment. It can be proved through the website of the China’s Ministry of Commerce.

4. We have provided different solutions for more than 500 users at China and abroad. We have rich experience in equipment’s actual use and Practical experience in case handling, which can fully solve various problems of customers.

Factory photo:

At the exhibition:

More our product

More industry

Treatable material

1. Before production, we will send the drawing of the product according to your requirements.

2. During the production process, we will regularly send you the production situation and pictures.

3. We will test the equipment before shipment, such as the magnetic intensity test, rotor dynamic balance experiment. And send you the photo and the video.

4. Warranty: 1 year. We will provide non-vulnerable accessories free during the warranty If you have any question, we will provide online video guidance. If online video guidance can not solve the problem, we will send engineers to your site for guidance. (Room and board expenses are negotiated separately.)

With well-equipped professional engineers and strong technical ability, our company has been in this field for 15 years.

1. We cooperate with superior suppliers (Nord &Schneider) to ensure the quality.

2. Tests of materials are freely checked for the required quality of the equipment before packing.

3. Engineers are always available to service for machinery commissioning overseas, which is not only after sales service support, but also technology support .

4."Keep Improving, Pursuing Excellence" would be kept forever.

Our certification:

1. Wet type

In order to recommend the most suitable model, please let us know the material`s situation, including the composition , size ,handling capacity and ferrous content.

2.Dry type

In order to recommend the most suitable model, please let us know

1.the material`s situation .including the composition , size ,handling capacity and ferrous content.

2.the material thickness transported on conveyor .

3.The width of conveyor bel

3.Which type should I use for my recycling plant?

In order to recommend the most suitable model, please let us know follow info:

1.material`s situation .including the composition , size ,handling capacity and ferrous content

2.the material thickness transported on conveyor belt.

3.The shape and width of the conveyor belt .

We solemnly promise a one-year warranty.

Eddy Current Separator Recycling Machine for Medical Glass Scraps

Medical Glass Scraps Containing Aluminum and Copper Recycling Machine

The Magnetic Separating System for waste Scrap is used for medical glass recycling. It can separate iron and nonferrous metals (copper and aluminum)from glass scraps efficiently. This system contains feeder, hooper, conveyor system, vibrator feeder and eddy current separator, etc. And it can be customized to fit the client's needs and will handle multiple tons per hour. Densen also could provide the suitable recycling solutions according to customers’ requirement, such as solid waste sorting line, aluminum recycling line, papermaking waste sorting lines, and scrap steel recycling line.

Description | Eddy Current Separator for Separating Copper Aluminium from meidical glass scraps |

Type | Aluminium copper plastic separator machine |

Application | Foundry, Plastic, E-Waste, Aluminum Industries |

Imported parts | Nord Gear Motor, Sigeling Belt and Schneider Electric parts |

Safety Protective Faclities | Emergency Stop and Open-cover Reset Button |

Design Support | Pro-E, UG,SolidWorks,AutoCad, PDF |

Quality Control | Material, Dimension,Performance |

After-sales Service Provided | Engineers available to service machinery overseas for 1 year |

Products show:

Details:

Workshops

Standard Features and Benefits:

1. the special feature is the eccentric pole system, it is adjustable,

2. compared to concentric pole systems, the eccentric pole system increases the metal yield by 50%.

3. assembled with imported components,

4.advanced smooth systerm. service life of the belt and drum shell is considerably lengthened.

Specification:

The separation process

Our engineers can design drawings or make a recommendationbased on your needs.

Example:

Declaration:

Products shown herein are made to the requirements of specific customers and are illustrative of the types of manufacturing capabilities available within Densen group of companies.

Our policy is that none of these products will be sold to 3rd parties without written consent of the customers to whom the tooling, design and specifications belong.

Our factory is Located in shanyang ,China, which is a professional enterprise producing magnetic series products. Our factory has been focusing on designing and manufacturing magnetic equipment for 12 years since 2006.We are one of the earliest suppliers of magnetic separator and eddy current separator in Asia. Main products are Eddy current separator, magnetic separator, belt magnetic separator, Drum magnetic separator and Grate magnets.

Our Advantage:

1. We have 13 years of professional production experience, and we are one of the earliest manufacturer of eddy current separator in China.

2. We have a technical engineer team with 10 engineers who have more than 25 years of working experience in eddy current separator.

3. In the list of 98 China National fixed appliances dismantling of the plant, there are 55 factories use our equipment. It can be proved through the website of the China’s Ministry of Commerce.

4. We have provided different solutions for more than 500 users at China and abroad. We have rich experience in equipment’s actual use and Practical experience in case handling, which can fully solve various problems of customers.

Factory photo:

At the exhibition:

More our product

More industry

Treatable material

1. Before production, we will send the drawing of the product according to your requirements.

2. During the production process, we will regularly send you the production situation and pictures.

3. We will test the equipment before shipment, such as the magnetic intensity test, rotor dynamic balance experiment. And send you the photo and the video.

4. Warranty: 1 year. We will provide non-vulnerable accessories free during the warranty If you have any question, we will provide online video guidance. If online video guidance can not solve the problem, we will send engineers to your site for guidance. (Room and board expenses are negotiated separately.)

With well-equipped professional engineers and strong technical ability, our company has been in this field for 15 years.

1. We cooperate with superior suppliers (Nord &Schneider) to ensure the quality.

2. Tests of materials are freely checked for the required quality of the equipment before packing.

3. Engineers are always available to service for machinery commissioning overseas, which is not only after sales service support, but also technology support .

4."Keep Improving, Pursuing Excellence" would be kept forever.

Our certification:

1. Wet type

In order to recommend the most suitable model, please let us know the material`s situation, including the composition , size ,handling capacity and ferrous content.

2.Dry type

In order to recommend the most suitable model, please let us know

1.the material`s situation .including the composition , size ,handling capacity and ferrous content.

2.the material thickness transported on conveyor .

3.The width of conveyor bel

3.Which type should I use for my recycling plant?

In order to recommend the most suitable model, please let us know follow info:

1.material`s situation .including the composition , size ,handling capacity and ferrous content

2.the material thickness transported on conveyor belt.

3.The shape and width of the conveyor belt .

We solemnly promise a one-year warranty.

| | Floor 21, Block B, Fortune Building, No. 18 Xinghua Bei Street , Tiexi District, Shenyang, 110025, China. |

| | 86 15541524932 |

| | contact@sydensen.com |