- Home

- Factories

- Processes

- Products

- News

- Download

- Contact Us

| Availability: | |

|---|---|

| Quantity: | |

GL2

DS

Densen Customized special grinder paper belt type magnetic coolant separator filter equipment for removing iron and impurities

GL2 series paper belt grinder iron remover:

It consists of transmission mechanism, chain, chain net and Command machine. The dirty liquid containing a large amount of impurities during work is first separated by a magnetic roller separator to separate a large amount of magnetic material, and then filtered on the paper strip. When the dirty liquid passes through the paper strip, fine magnetic material and impurities are adsorbed on the surface of the paper strip. Cutting and impurities gradually accumulate until the paper tape is clogged. At this time, the liquid level of the dirty liquid rises, floats the float, the sending mechanism sends a message, the speed reducer drives the chain and the chain net to move the dirt and dirty paper into the sewage tank, and the dirty liquid The liquid level drops, the sending mechanism sends a message, the speed reducer stops working, and the machine enters the next working cycle, thus realizing the automatic updating of the paper strip.

Features

1: It can fully filter all kinds of metals in the coolant (oil), non-metallic impurities

2: The filtration effect reaches 90%-98%, the precision can reach 15-40um, and automatic control can be realized.

3: The coolant can be cooled with constant temperature to meet the requirements of the coolant temperature.

Scope of application:

It can be used for precision grinding machines and finishing machines with large cutting fluid volume.

Product show:

Example drawing:

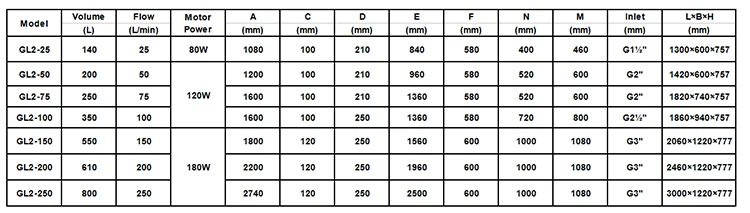

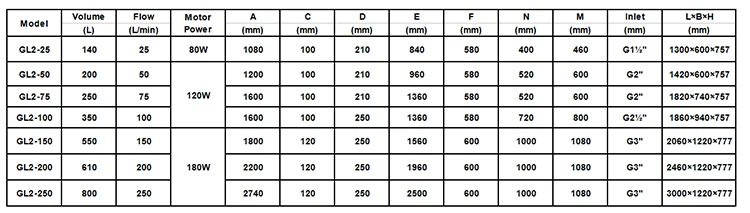

Product specification:

We can customized model according your need

Our factory is Located in shanyang ,China, which is a professional enterprise producing magnetic series products. Our factory has been focusing on designing and manufacturing magnetic equipment for 13 years since 2006.We are one of the earliest suppliers of magnetic separator and eddy current separator in Asia. Main products are Eddy current separator, magnetic separator, belt magnetic separator, Drum magnetic separator and Grate magnets.

Our Advantage:

1. We have 13 years of professional production experience, and we are one of the earliest manufacturer of eddy current separator in China.

2. We have a technical engineer team with 10 engineers who have more than 25 years of working experience in eddy current separator.

3. In the list of 98 China National fixed appliances dismantling of the plant, there are 55 factories use our equipment. It can be proved through the website of the China’s Ministry of Commerce.

4. We have provided different solutions for more than 500 users at China and abroad. We have rich experience in equipment’s actual use and Practical experience in case handling, which can fully solve various problems of customers.

Factory photo:

At the exhibition:

More our product

More industry

Treatable material

1. Before production, we will send the drawing of the product according to your requirements.

2. During the production process, we will regularly send you the production situation and pictures.

3. We will test the equipment before shipment, such as the magnetic intensity test, rotor dynamic balance experiment. And send you the photo and the video.

4. Warranty: 1 year. We will provide non-vulnerable accessories free during the warranty If you have any question, we will provide online video guidance. If online video guidance can not solve the problem, we will send engineers to your site for guidance. (Room and board expenses are negotiated separately.)

With well-equipped professional engineers and strong technical ability, our company has been in this field for 15 years.

1. We cooperate with superior suppliers (Nord &Schneider) to ensure the quality.

2. Tests of materials are freely checked for the required quality of the equipment before packing.

3. Engineers are always available to service for machinery commissioning overseas, which is not only after sales service support, but also technology support .

4."Keep Improving, Pursuing Excellence" would be kept forever.

Our certification:

1. Wet type

In order to recommend the most suitable model, please let us know the material`s situation, including the composition , size ,handling capacity and ferrous content.

2.Dry type

In order to recommend the most suitable model, please let us know

1.the material`s situation .including the composition , size ,handling capacity and ferrous content.

2.the material thickness transported on conveyor .

3.The width of conveyor bel

3.Which type should I use for my recycling plant?

In order to recommend the most suitable model, please let us know follow info:

1.material`s situation .including the composition , size ,handling capacity and ferrous content

2.the material thickness transported on conveyor belt.

3.The shape and width of the conveyor belt .

We solemnly promise a one-year warranty.

Contact information:

Densen Customized special grinder paper belt type magnetic coolant separator filter equipment for removing iron and impurities

GL2 series paper belt grinder iron remover:

It consists of transmission mechanism, chain, chain net and Command machine. The dirty liquid containing a large amount of impurities during work is first separated by a magnetic roller separator to separate a large amount of magnetic material, and then filtered on the paper strip. When the dirty liquid passes through the paper strip, fine magnetic material and impurities are adsorbed on the surface of the paper strip. Cutting and impurities gradually accumulate until the paper tape is clogged. At this time, the liquid level of the dirty liquid rises, floats the float, the sending mechanism sends a message, the speed reducer drives the chain and the chain net to move the dirt and dirty paper into the sewage tank, and the dirty liquid The liquid level drops, the sending mechanism sends a message, the speed reducer stops working, and the machine enters the next working cycle, thus realizing the automatic updating of the paper strip.

Features

1: It can fully filter all kinds of metals in the coolant (oil), non-metallic impurities

2: The filtration effect reaches 90%-98%, the precision can reach 15-40um, and automatic control can be realized.

3: The coolant can be cooled with constant temperature to meet the requirements of the coolant temperature.

Scope of application:

It can be used for precision grinding machines and finishing machines with large cutting fluid volume.

Product show:

Example drawing:

Product specification:

We can customized model according your need

Our factory is Located in shanyang ,China, which is a professional enterprise producing magnetic series products. Our factory has been focusing on designing and manufacturing magnetic equipment for 13 years since 2006.We are one of the earliest suppliers of magnetic separator and eddy current separator in Asia. Main products are Eddy current separator, magnetic separator, belt magnetic separator, Drum magnetic separator and Grate magnets.

Our Advantage:

1. We have 13 years of professional production experience, and we are one of the earliest manufacturer of eddy current separator in China.

2. We have a technical engineer team with 10 engineers who have more than 25 years of working experience in eddy current separator.

3. In the list of 98 China National fixed appliances dismantling of the plant, there are 55 factories use our equipment. It can be proved through the website of the China’s Ministry of Commerce.

4. We have provided different solutions for more than 500 users at China and abroad. We have rich experience in equipment’s actual use and Practical experience in case handling, which can fully solve various problems of customers.

Factory photo:

At the exhibition:

More our product

More industry

Treatable material

1. Before production, we will send the drawing of the product according to your requirements.

2. During the production process, we will regularly send you the production situation and pictures.

3. We will test the equipment before shipment, such as the magnetic intensity test, rotor dynamic balance experiment. And send you the photo and the video.

4. Warranty: 1 year. We will provide non-vulnerable accessories free during the warranty If you have any question, we will provide online video guidance. If online video guidance can not solve the problem, we will send engineers to your site for guidance. (Room and board expenses are negotiated separately.)

With well-equipped professional engineers and strong technical ability, our company has been in this field for 15 years.

1. We cooperate with superior suppliers (Nord &Schneider) to ensure the quality.

2. Tests of materials are freely checked for the required quality of the equipment before packing.

3. Engineers are always available to service for machinery commissioning overseas, which is not only after sales service support, but also technology support .

4."Keep Improving, Pursuing Excellence" would be kept forever.

Our certification:

1. Wet type

In order to recommend the most suitable model, please let us know the material`s situation, including the composition , size ,handling capacity and ferrous content.

2.Dry type

In order to recommend the most suitable model, please let us know

1.the material`s situation .including the composition , size ,handling capacity and ferrous content.

2.the material thickness transported on conveyor .

3.The width of conveyor bel

3.Which type should I use for my recycling plant?

In order to recommend the most suitable model, please let us know follow info:

1.material`s situation .including the composition , size ,handling capacity and ferrous content

2.the material thickness transported on conveyor belt.

3.The shape and width of the conveyor belt .

We solemnly promise a one-year warranty.

Contact information:

| | Floor 21, Block B, Fortune Building, No. 18 Xinghua Bei Street , Tiexi District, Shenyang, 110025, China. |

| | 86 15541524932 |

| | contact@sydensen.com |